SludgeVision™

SludgeVision™

SludgeVision is a technology designed to optimize the sludge dewatering process in wastewater treatment plants, specifically for use with gravity belt press equipment. It combines hardware and software to assist plant operators in controlling the polymer dose required for optimal sludge dewatering. The result? Unprecedented savings, improved performance, and a more sustainable process.

The Science of Smarter Dewatering

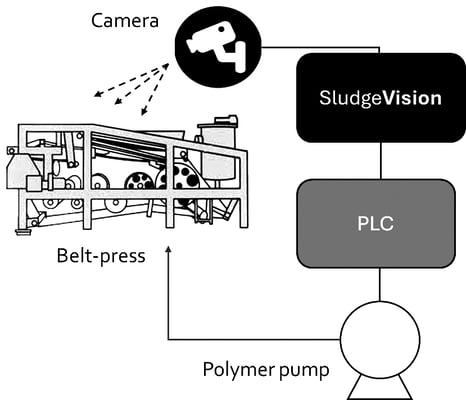

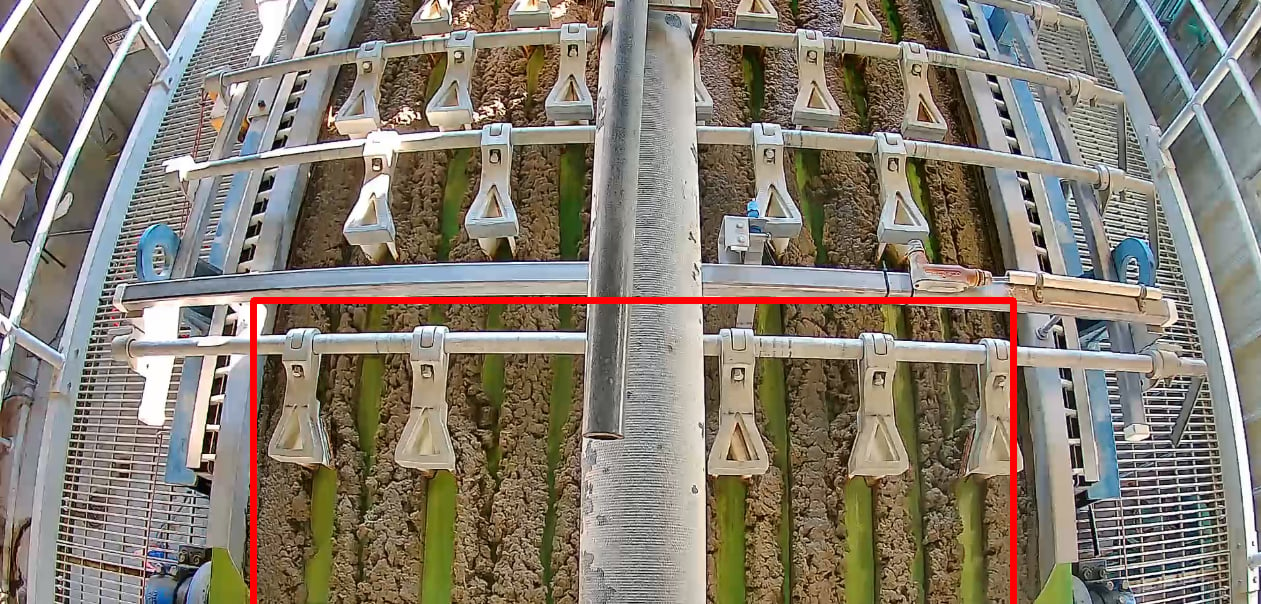

SludgeVision uses a strategically mounted camera and a Base Station to continuously monitor your gravity belt press. The system’s computer vision algorithms analyze the visible fractions of sludge and belt in real-time, providing immediate insights into dewatering efficiency. This feedback enables operators to make on-the-fly adjustments or integrate SludgeVision into existing PLC/SCADA systems for automated polymer dosage control.

How We Achieve Optimal Dewatering Performance

SludgeVision transforms sludge dewatering from a heuristic, labor-intensive practice into a data-driven, automated process control application.

- Real-time Monitoring: The camera captures a live feed of your belt press, feeding data directly to the SludgeVision software.

- Intelligent Analysis: The software processes this visual data to determine the optimal polymer dose needed for effective sludge separation.

- Actionable Feedback: The data is translated into real-time feedback that can be used by operators or integrated into your existing PLC/SCADA systems for automated polymer dosage control.

- Fail-safe Mode: The system has a built-in fail-safe (Safe Mode). If the camera feed is lost or communication is interrupted, it automatically reverts to a safe, predefined pump speed to prevent over- or under-dosing.

SludgeVisionTM Polymer Control System (SV-PCS)

The SludgeVision PCS combines a non-invasive, real-time HD camera, a computer-vision engine, and a control system designed for sludge dewatering using belt presses. It continuously monitors sludge dewatering, delivering immediate insights into belt-press performance.

Key Features

- Non-invasive: Camera mounted above the belt press.

- Computer Vision: Real-time analysis of sludge dewatering performance.

- Automation: Polymer pump dosage is controlled by the HMI/PLC and SludgeVision’s control algorithm.

- Fail-safe mode: Reverts to safe mode if alarms or anomalies are encountered.

Technical Specifications:

- Camera: High-Definition IP camera, PoE, 1920x1080 resolution, IP68 rated.

- SludgeVision Base Station: Industrial minicomputer, 10.1" touchscreen running SludgeVision software, CPU: Quadcore ARM Cortex-A72, 8GB RAM, 128GB SSD storage.

- Communications: Modbus TCP: 10/100 Mbps Ethernet, Modbus RTU serial RS485, Analog: 4–20 mA.

Key Benefits: Save Time, Money, and Resources

Time Savings: Operators can step away from constant monitoring and focus on other tasks.

Polymer Savings: Maintain optimal dosage and reduce chemical usage, lowering operational costs.

Consistent Performance: Real-time control ensures reliable sludge separation quality, even as sludge composition and belt-press conditions fluctuate.

What is the SludgeVision Base Station?

The Base Station is an industrial-grade computer that serves as the central hub for the system, hosting the SludgeVISION software and managing all data.

What if the belt is dirty?

SludgeVision is designed to handle this. Its algorithms are trained to differentiate between the sludge and the belt, ensuring accurate analysis even with a dirty belt or inconsistent belt color.

What if I lose communication?

The system has a built-in fail-safe (Safe Mode). If the camera feed is lost or communication is interrupted, the system automatically reverts to a safe, predefined pump speed to prevent over- or under-dosing.

Can I use SludgeVision to optimize other variables?

Yes. While its primary function is polymer dosage control, the system’s analytical capabilities can be expanded to provide insights for optimizing other parameters, such as belt press speed.

Let's get the conversation started

Tell us a little bit about you and the information you’re looking for and we'll send you information by email about the topics you are interested in. Check the box to have a cleanwater1 expert contact you within one business day.

Additional Resources

Learn At Your Pace

By subscribing to our learning track, you will receive emails featuring videos, webinar invites, informative articles and more.

View Our Online Library

Featuring brochures, case studies, data sheets and more. Filter by product category, brand, location, use case or document type.

Connect With Us

Contact a member of our team using our online form, by email or give us a call. We look forward to speaking with you.