Liquid Polymer Activation

The Science of Liquid Polymer Activation

How It Works

Liquid polymer activation is a process used in water and wastewater treatment to enhance the flocculation and sedimentation of suspended solids in wastewater. Liquid polymers are long-chain molecules that can help to bind together the small particles of suspended solids in water and wastewater and form larger, heavier flocs that can settle more easily.

The activation of the liquid polymer can be achieved through a variety of means, including mechanical mixing, agitation, or the addition of other chemicals such as coagulants or flocculants. The activation process is typically optimized for each specific application to ensure that the polymer is activated in the most effective way possible to achieve the desired results.

Achieving High Shear Mixing is the Key

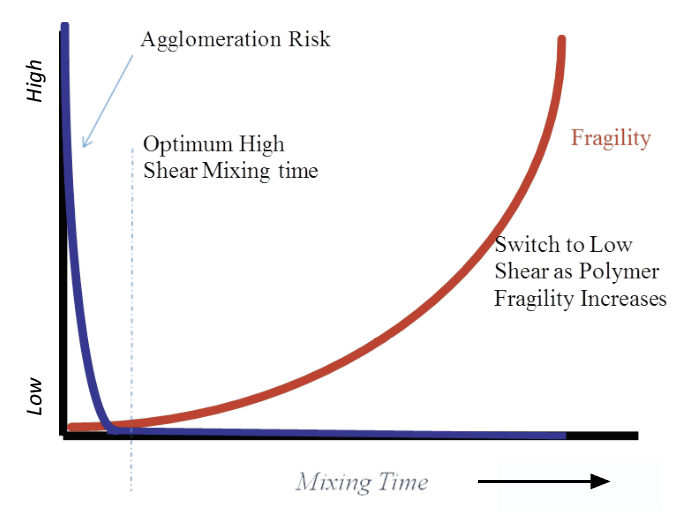

Polymers vastly improve the operations of water and wastewater plants by accelerating the settling of particles and improving sludge dewatering. Polymers - emulsion and dry - require the application of different levels of energy at different times to get the optimal “uncoiling” of the polymer chains without damaging or shortening the polymer chain. High shear mixing is required to prevent agglomerations, but over-mixing can damage the polymer. The key is to shift mixing energy over time to get the optimal results.

The key is to shift mixing energy over time to get the optimal results.

The Science of Efficient Polymer Activation

High Energy at MOIW

+

Transition to Low-Energy "Quiescent Zone"

+

=

Fully Activated Polymer Solution at Desired Concentration

We Follow the Science

Our systems are designed to optimize polymer performance because they follow the latest in polymer science. These fundamental aspects are demonstrated by the following core elements of our feeders:

- Two stage mixing with the highest energy applied first at the moment of initial wetting (MOIW) followed by a "quiescent" zone allowing for more gentle activation as polymer science dictates.

- Extended residence time in the "quiescent" zone to optimize the continued charge site exposure as the polymer is activated in an optimal manner.

- Options for pneumatic conveyance (dry polymer), economic mix tank design and secondary dilution to fit any site condition and application challenge.

- Control options to fit any site condition and application challenge.

Proper Polymer Activation is The Key to Lower Costs and Higher Effectiveness

While polymers vastly improve the operation of water and wastewater plants by accelerating the settling of particles and improving sludge dewatering, polymer costs are one of the largest operating expenses at a plant. Even a small reduction in polymer consumption can result in meaningful savings.

Proper polymer activation is the key to maximizing polymer effectiveness.

Our Liquid Polymer Activation Solutions

Polyblend®

The two‐zone Polyblend® mixing regimen is widely recognized by polymer experts as the proper mixing methodology to optimize polymer activation.

Dynablend™

The Dynablend™ liquid polymer blending systems are proven to be the most effective and reliable hydraulic polymer activation technology.

VeloBlend™

The VeloBlend's hybrid polymer activation technology combines the reliability of non-mechanical blending with controllable, variable speed hydro-mechanical mixing energy.

Miniblend™

Miniblend™ has easy-to-use controls and utilizes hydroaction concentric mixing chambers to activate simple-to-blend and difficult-to-blend polymers.

Let's get the conversation started

Tell us a little bit about you and the information you’re looking for and we'll send you information by email about the topics you are interested in. Check the box to have a cleanwater1 expert contact you within one business day.

Additional Resources

Learn At Your Pace

By subscribing to our learning track, you will receive emails featuring videos, webinar invites, informative articles and more.

View Our Online Library

Featuring brochures, case studies, data sheets and more. Filter by product category, brand, location, use case or document type.

Connect With Us

Contact a member of our team using our online form, by email or give us a call. We look forward to speaking with you.