Water Quality

6 Ways To Achieve Superior Water Quality

cleanwater1 is a leading provider of water quality solutions and the only to offer a complete set of end-to-end water quality and wastewater treatment products and solutions.

cleanwater1 pairs proven brands like Polyblend®, Dynablend™, VeloBlend™,PAX Mixers, Monoclor® RCS and Microclor®, with cutting edge strategies and innovations to help customers meet and exceed water quality goals and regulations.

cleanwater1's water quality solutions focus on disinfection, residual management, THM reduction, tank mixing, liquid polymer feed and dry polymer feed to achieve high water quality outcomes.

Watch our Webinar on THM Mitigation in Water Distribution Systems through Water Storage Tank Mixing and Aeration

Gain a practical understanding of the conditions, chemistry, and science behind trihalomethane (THMs) generation in water distribution systems.

Disinfection

Disinfection is an essential component of water quality management because it helps to protect public health by reducing the risk of waterborne diseases. Water can contain harmful bacteria, viruses, and other pathogens that can cause illness or even death if consumed.

Disinfection is the process of killing or inactivating microorganisms. Disinfection is typically achieved through the use of chemical disinfectants, such as chlorine, chloramine, or ozone. Disinfection is especially critical in areas where the water source is surface water, such as lakes or rivers, as these sources can be more vulnerable to contamination.

Effective disinfection requires careful management and monitoring to ensure that the appropriate levels of disinfectant are present in the water supply. The goal is to provide protection against waterborne diseases while minimizing the risk of harmful byproducts or other adverse effects.

On-site hypochlorite generation (OSHG) systems for disinfection have seen an increased adoption rate in the last decade as water and wastewater utilities continue to grapple with the onerous complexity of risk management plans (RMPs) in the case of gas chlorine disinfection and the operational or cost challenges of using bulk 12.5% sodium hypochlorite for disinfection. The latest generation of OSHG systems have been designed to emphasize safety, reliability and maintainability.

Disinfection is an essential aspect of water quality management that helps to protect public health and ensure that drinking water is safe and healthy for consumption.

By maintaining an appropriate disinfectant residual in drinking water, we can ensure that our water supply remains as safe and healthy as possible for all consumers.

Residual Management

Residual management is an essential aspect of maintaining water quality management. It refers to the process of maintaining a residual amount of chlorine disinfectant in drinking water to ensure that it remains safe to drink by killing harmful microorganisms that may be present in the water.

Disinfectants such as chlorine, chloramine, and ozone are commonly used to treat drinking water to eliminate harmful bacteria, viruses, and other pathogens. However, the disinfectant must remain in the water high enough level to ensure that the water stays safe as it travels through pipes and storage tanks to reach consumers.

Disinfectant residual management involves monitoring the level of disinfectant in the water supply and adjusting the dosage as needed to maintain the proper amount of residual. The goal is to ensure that the disinfectant is present at a level sufficient to provide protection against waterborne diseases, and to counteract the effects of water age and nitrification.

Effective disinfectant residual management requires a combination of regular monitoring, careful dosage adjustments, and proper maintenance of water treatment equipment.

THM Reduction

Trihalomethane (THM) aeration is a water treatment process used to reduce the levels of trihalomethanes in drinking water. Trihalomethanes are a group of chemicals that can form when chlorine, used for disinfecting water, reacts with natural organic matter present in the water. The four most common THMs are chloroform, bromodichloromethane, dibromochloromethane, and bromoform. These compounds are of concern because they have been linked to potential health risks, including an increased risk of cancer. Exceeding the Maximum contaminant level (MCL) of THMs is one of the most common water quality violations in the United States. THM aeration is particularly effective because trihalomethanes are volatile organic compounds (VOCs), which means they can easily evaporate from water into the air. By aerating the water, THMs are transferred from the liquid phase into the gaseous phase (air), effectively reducing their concentration in the water.

THM (trihalomethane) aeration has become more popular in recent years due to stricter regulations on water quality, heightened public awareness about the health risks associated with THMs, and advancements in aeration technology. THM aeration has a relatively low capital cost, low operating costs, and can have a phased implementation approach. Changing water source quality and a more holistic approach to water management have also contributed to the adoption of THM aeration as a key strategy in reducing these harmful byproducts in drinking water.

THM reduction is an important aspect of maintaining high-quality drinking water, and it requires ongoing monitoring and management to ensure that water supplies remain safe and healthy for all consumers.

Tank Mixing

Water storage tank mixing plays a crucial role in maintaining and improving water quality in storage tanks. Here’s how it contributes to this goal:

- Prevents Stratification: Water in large storage tanks tends to stratify, or form layers of different temperatures. Stratification can lead to uneven water quality within the tank, with warmer water at the top and cooler water at the bottom. Mixing helps in maintaining a uniform temperature throughout the tank, preventing stratification and the associated water quality issues.

- Reduces Stagnation: Without adequate mixing, areas of stagnant water can develop within the tank. Stagnation can lead to the growth of bacteria, including harmful pathogens. Mixing ensures that water moves continuously, reducing the risk of bacterial growth and biofilm formation.

- Uniform Chemical Distribution: Chlorine and other disinfectants are often added to stored water to maintain water quality. Mixing ensures that these chemicals are evenly distributed throughout the tank, preventing areas of under- or over-chlorination and ensuring effective disinfection.

- Limits Sediment Accumulation: Over time, sediment can accumulate at the bottom of storage tanks, which can harbor bacteria and other contaminants. Mixing helps to keep these particles in suspension, preventing significant build-up and making it easier to remove them during routine cleaning.

- Improves Dissolved Oxygen Levels: Adequate mixing can help maintain appropriate levels of dissolved oxygen throughout the tank. This is important for preventing anaerobic conditions, which can lead to the growth of certain undesirable bacteria and the production of unpleasant tastes and odors.

- Balances Water Age: In water treatment, “water age” refers to the time water spends in the distribution system, including storage tanks. Older water can see a decline in quality. Mixing helps in circulating water within the tank, thereby reducing water age and maintaining fresher, higher-quality water.

- Prevents Ice Formation in Cold Climates: In colder climates, mixing can prevent the formation of ice in storage tanks, which can damage the tank and degrade water quality.

Overall, effective water storage tank mixing is a key component in ensuring the safety, quality, and palatability of stored drinking water. It is an important consideration in water system design and maintenance, particularly in systems where water may remain in storage for extended periods.

Tank mixing can help improve water quality.

Liquid polymer feed is an effective and cost-efficient method for improving water quality in various applications, including municipal drinking water treatment, industrial wastewater treatment, and water treatment for agricultural and aquaculture applications.

Liquid Polymer Feed

Liquid polymer feed can improve water quality by removing suspended particles and impurities from water through a process known as flocculation.

When liquid polymer is added to water, it forms long chains of molecules known as polymers. These polymers attract and bind to small particles and impurities in the water, forming larger clusters known as flocs.

The flocs are then heavier and denser than the water, causing them to settle to the bottom of the water or float to the top, making it easier to remove them through sedimentation or filtration processes.

By removing these particles and impurities, liquid polymer feed can improve water clarity, reduce turbidity, and remove harmful contaminants such as bacteria, viruses, and heavy metals. This makes the water safer to drink and use for other purposes.

Dry Chemical Feed

Dry chemical feed is a method of adding chemical coagulants or flocculants to water for the purpose of removing suspended particles and impurities.

The dry chemical is typically stored in bags or drums and is added to the water using a specialized feeder system. The feeder system can be manually operated or automated depending on the size and complexity of the water treatment system.

Dry chemical feed has some advantages over liquid polymer feed. For example, it can be more convenient to transport and store, and it can be easier to handle in smaller applications. However, dry chemical feed can be more difficult to handle and mix with the water which can result in lower treatment efficiency. It can also be more expensive in larger water treatment applications.

Overall, the choice between dry chemical feed and liquid polymer feed depends on the specific water treatment application and the characteristics of the water being treated. Both methods can be effective in removing impurities and improving water quality, but the selection of the most suitable method will depend on a range of factors such as cost, efficiency, ease of handling, and water treatment objectives.

The dry chemical powder can include a variety of chemical coagulants or flocculants, such as aluminum sulfate, ferric chloride, or calcium hydroxide, among others. The specific chemical used will depend on the characteristics of the water being treated and the specific impurities that need to be removed.

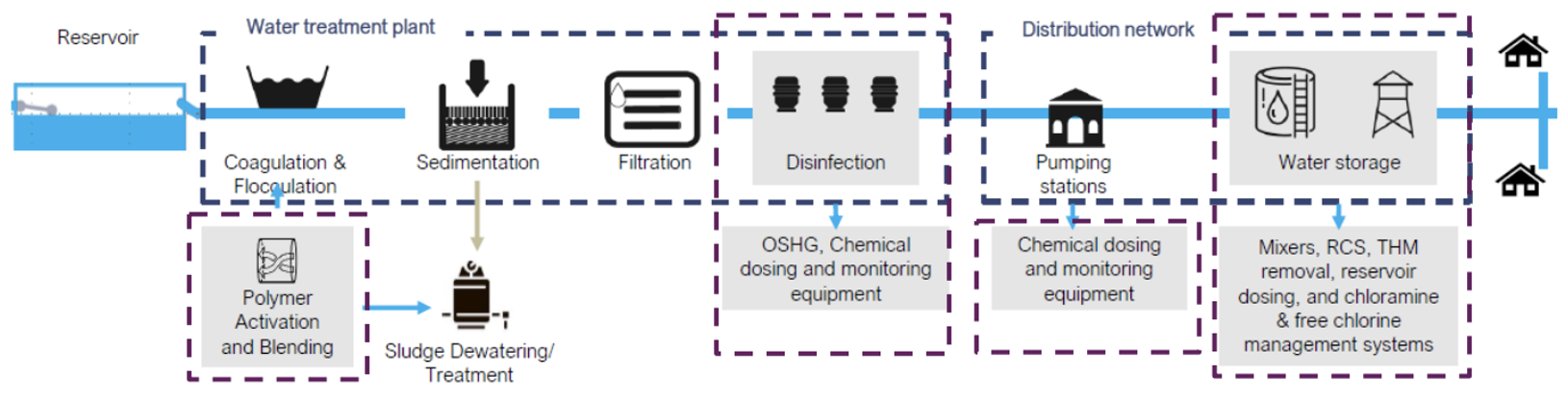

How We Treat Water

Let's get the conversation started

Tell us a little bit about you and the information your looking for and we'll send you information relevant to your role and the topics you are interested in. If you would like a cleanwater1 expert to contact you, make sure to check the box in the form giving us permission to contact you.

Additional Resources

Learn At Your Pace

By subscribing to our learning track, you will receive emails featuring videos, webinar invites, informative articles and more.

View Our Online Library

Featuring brochures, case studies, data sheets and more. Filter by product category, brand, location, use case or document type.

Connect With Us

Contact a member of our team using our online form, by email us or give us a call. We look forward to speaking with you.