Dry Chemical Feed Series

Dry Chemical Feed Equipment and Controls Series

A Variety of Options to Choose From

We offer a variety of technologies for feeding and metering dry chemicals commonly used in the treatment of municipal and industrial water and wastewater.

Our extensive line of volumetric screw and gravimetric feeders, feeder tank systems, and accessories can handle the most commonly used chemicals in the municipal water applications such as calcium oxide, calcium hydroxide, ferric sulfate, soda ash, potassium permanganate, aluminum sulfate, and carbon. Chemicals used in industrial processes include bleach, clay, gypsum, plastic pellets, pigments, and flour.

Typical applications include:

- Neutralization

- pH control

- Coagulation

- Sedimentation

- Fluoridation

- Sludge Control

- Softening

- S02

- Odor control

- Dry Ingredients

Series 32-055 Volumetric Feeder

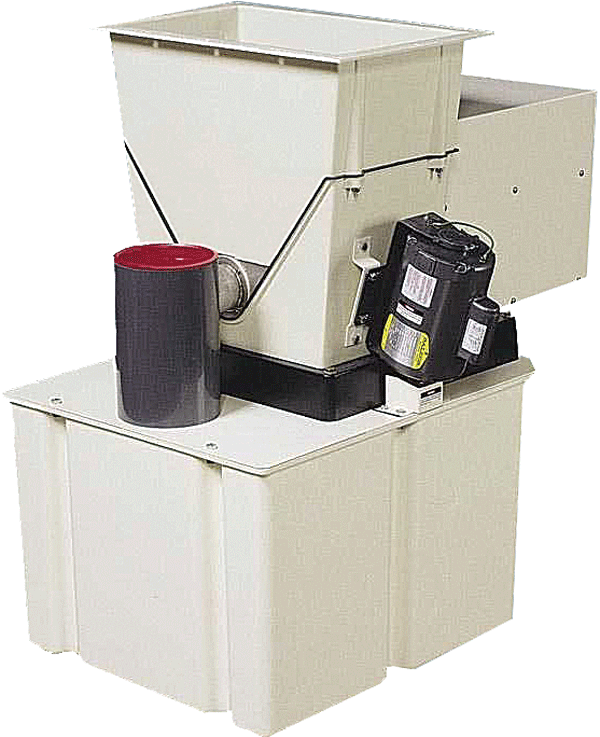

Series 35-150 Tank Feed System

Tank Feed System, Series 35-150, Tailored to Your Needs

The Series 35-150 chemical feeder solution tank system is designed for preparing large or small volumes of solution from dry chemicals for water and waste treatment applications.

Although this system is a pre-engineered, packaged system, built with standard components to keep costs low, it can be tailored to almost any installation requirement. There is no need to pay for functions that will never be used, or to settle for too little or too much capacity or control.

Features:

- Economical system that gives better results than a do-it-yourself system

- Pre-engineered for efficient operation

- Wide choice of arrangements

- Custom system from stock components

- Rugged feeder

- Pre-tested and economical to install

- Optional accessories

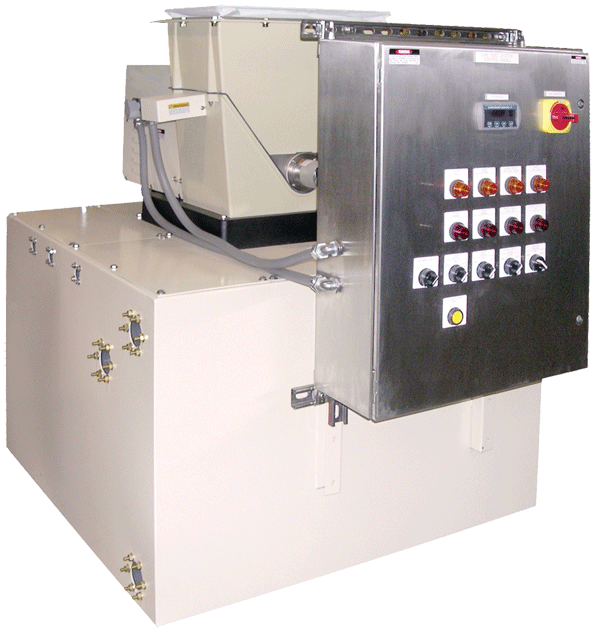

Series 32-050 and 32-055 Volumetric Feeders

The Series 32-050 and 32-055 Volumetric Screw Feeders are designed to feed a wide range of water and wastewater treatment chemicals as well as industrial process chemicals and dry materials.

Options include: Four different feed screw sizes and capacities from 0.03 to 50 cubic feet. The continuous operating range is 20:1, extendable to 60:1 by belt position on a stepped pulley.

Series 32-050 Feeder

This economical feeder features a constant speed feed screw that is controlled by a manually-set percent timer. The feeder cycles on and off over a one minute feed cycle depending on the timer setting.

Series 32-055 Feeder

This highly adaptable feeder features a variable speed feed screw with four different control arrangements:

- Manual control via a feeder mounted potentiometer

- Start-stop control from a remote interlock

- mA control from a flow signal or remote plant control.

- mA control from a flow signal or remote plant control with 4-20mA transmitter feedback

- Rugged, corrosion resistant construction for long service life

- Design simplicity for reliable operation with minimal maintenance

- Various control options-manual to fully automatic

- Accuracy of 1% to 2% full scale with free flowing materials

- Wide operating range

- Integral hopper agitation for difficult-to-handle materials

- Hopper low level switch and vibrator options

- Special arrangements for carbon and potassium permanganate

- Hazardous location arrangement (FM approved)

- Food-grade arrangement available for industrial applications

Series 32-055 Volumetric Feeder

Barracuda Volumetric Auger Feeders

The feeder is the heart of our systems. As a stand-alone component, a properly sized feeder can meter a specified amount of product into a finished package. As an integral part of a system, the same properly sized feeder can meter minor ingredients to a food batching system, lime or polymer into an environmental water system or chemicals into a fertilizer blend.

Features:

- Barracuda volumetric feeder with overwind & hopper vibrator material conditioning (see Barracuda brochure for feed rate options)

- Mix tank or wetting cone with dilution water control system

- Batch level control, direct feed flow-through over-flow or metered control options

- Stainless steel construction (304 standard)

Optional Accessories

- Custom Auger Sizes

- Overwind Conditioning Auger

- Vibrator & Timer Assembly

- Extension Hoppers

- Bag Dump Station

- Level Sensors

- Scale for Loss in Weight

- Feeder Stand

- Drop-Out Bottom Hopper

Technical Data

Barracuda 500A Volumetric Feeder

- Feed Range: Up to .09 ft^3/hr

- Construction: 304 S.S. Std.

- Integral Hopper: ½ Cubic Foot

- Gearmotor: 1/20 HP, 90 VDC

- Auger Sizes 3/8”-2” OD

- Auger Length: 18-3/16” St.

Barracuda 1000A Volumetric Feeder

- Feed Range: 0.02-12 ft3/hr

- Construction: 304 S.S. Std.

- Integral Hopper: 1 ft3

- Motor: ½ HP, 230/460 VAC

- Gear Reducer: 20:1

- Auger Sizes 3/8”-2” OD

- Auger Length: 24-3/16” Std

Barracuda 1500A Volumetric Feeder

- Feed Range: 0.02-12 ft3/hr

- Construction: 304 S.S. Std

- Integral Hopper: 1-1/2 ft3

- Motor: ½ HP, 230/460 VAC

- Gear Reducer: 20:1

- Auger Sizes 3/8”-2” OD

- Auger Length: 24-3/16” Std.

Barracuda 3000A Volumetric Feeder

- Feed Range: 12-100 ft3/hr

- Construction: 304 S.S. Std.

- Integral Hopper: 3 ft3

- Motor: 1½ HP, 230/460 VAC

- Gear Reducer: 20:1

- Auger Sizes 2”-4” OD

- Auger Length: 26-1/16” Std

Downloadable Documents

Let's get the conversation started

Tell us a little bit about you and the information you’re looking for and we'll send you information by email about the topics you are interested in. Check the box to have a cleanwater1 expert contact you within one business day.

Additional Resources

Learn At Your Pace

By subscribing to our learning track, you will receive emails featuring videos, webinar invites, informative articles and more.

View Our Online Library

Featuring brochures, case studies, data sheets and more. Filter by product category, brand, location, use case or document type.

Connect With Us

Contact a member of our team using our online form, by email or give us a call. We look forward to speaking with you.