Monoclor® RCS

Monoclor®RCS Residual Control System

Constant and Reliable. That's Monoclor® RCS.

Monoclor® RCS systems are designed to take the expense and complexity out of managing chloramine residual levels in distribution networks. By automatically managing chloramine residual levels in strategically located reservoirs, utilities no longer have to engage in costly procedures such as chlorinating/super-chlorinating tanks, emergency/manual tank boosting, reactionary testing, and aggressive tank cycling.

Monoclor® RCS is a control system that maintains free chlorine or chloramine residual within the reservoir in three ways: 1) by creating a homogeneous mixture through active mixing, 2) by applying chemicals rationally and predictably, and 3) by monitoring the response with control logic in real-time.

What Makes Monoclor® RCS Different

Managing water quality in drinking water distribution system is challenging since the chlorine or chloramine used is affected and acted upon by forces within the water, piping and tanks themselves. chlorine or chloramine, is not persistent. Water quality degrades as the water ages in the distribution system. Operators must carefully regulate residuals while reducing the potential for disinfection byproduct formation. Traditional tools to manage disinfectant levels in the distribution system can be costly, time-consuming, most times short lived. They are often described as short-term bandages that do not solve the root problem. Monoclor® RCS allows utilities to address this root problem by:

- Proactively controlling the chlorine/chloramine levels in tanks to provide a better overall distribution system residual which will help to prevent nitrification issues and coliform positives.

- Significantly reducing the need for wasteful and costly flushing, tank cycling/dumping, manual tank dosing, and tank climbing.

- Allows operators to toggle between chloramine and free chlorine modes as needed

- Is fully capable of SCADA integration and remote monitoring

- Has over 200 installations nationwide in tanks ranging in size from 100,000 gallons to over 50 million gallons

Monoclor® RCS systems automatically maintain chloramine residual set‐points in water storage tanks eliminating nitrification, coliform “hits”, unnecessary tank cycling, and manual tank boosting.

The Right Chemical at The Right Time

Powerful tank mixing is a key part of the Monoclor®RCS water quality solution. Our system utilizes the appropriately sized mixer to rapidly blend disinfectant into the entire tank volume.

The Monoclor® RCS system then samples the homogenized water and determines the appropriate chemical dosing strategy based on the disinfectant levels present in the reservoir.

Sophisticated control algorithms utilize real‐time tank sample data and automatically calculate the dosing of chemical for the particular tank based on the desired set‐point and tank’s position on the breakpoint curve. Reliable chemical dosing skids ensure precise ammonia and chlorine dosing into the Monoclor® RCS powerful in‐tank mixing zone.

By dosing the right chemical at the right time into a completely mixed tank, the Monoclor® RCS system quickly reaches and maintains the desired residual set‐point.

Backed by over 10 years of experience in improving distribution network water quality, the Monoclor® RCS system has 100+ installations nationwide in tanks ranging in size from 100,000 gallons to over 50 million gallons.

Four Ways Monoclor® RCS Maintains Disinfectant Residual Set-Points: Mix, Monitor, Intervene and Manage

By combining powerful tank mixing, advanced water quality sensors, an automated chemical dosing system and feedback loop, the Monoclor® RCS integrates four discrete functions to maintain disinfectant residual set-points.

MIX

Achieve complete disinfection homogenization, maintain chemical and thermal equilibrium.

MONITOR

Analyze and respond to changing tank conditions in real time.

INTERVENE

Dose disinfectant to achieve the desired disinfectant residual set-point.

MANAGE

Monitor tank equilibrium in real-time to automatically respond to changing tank conditions.

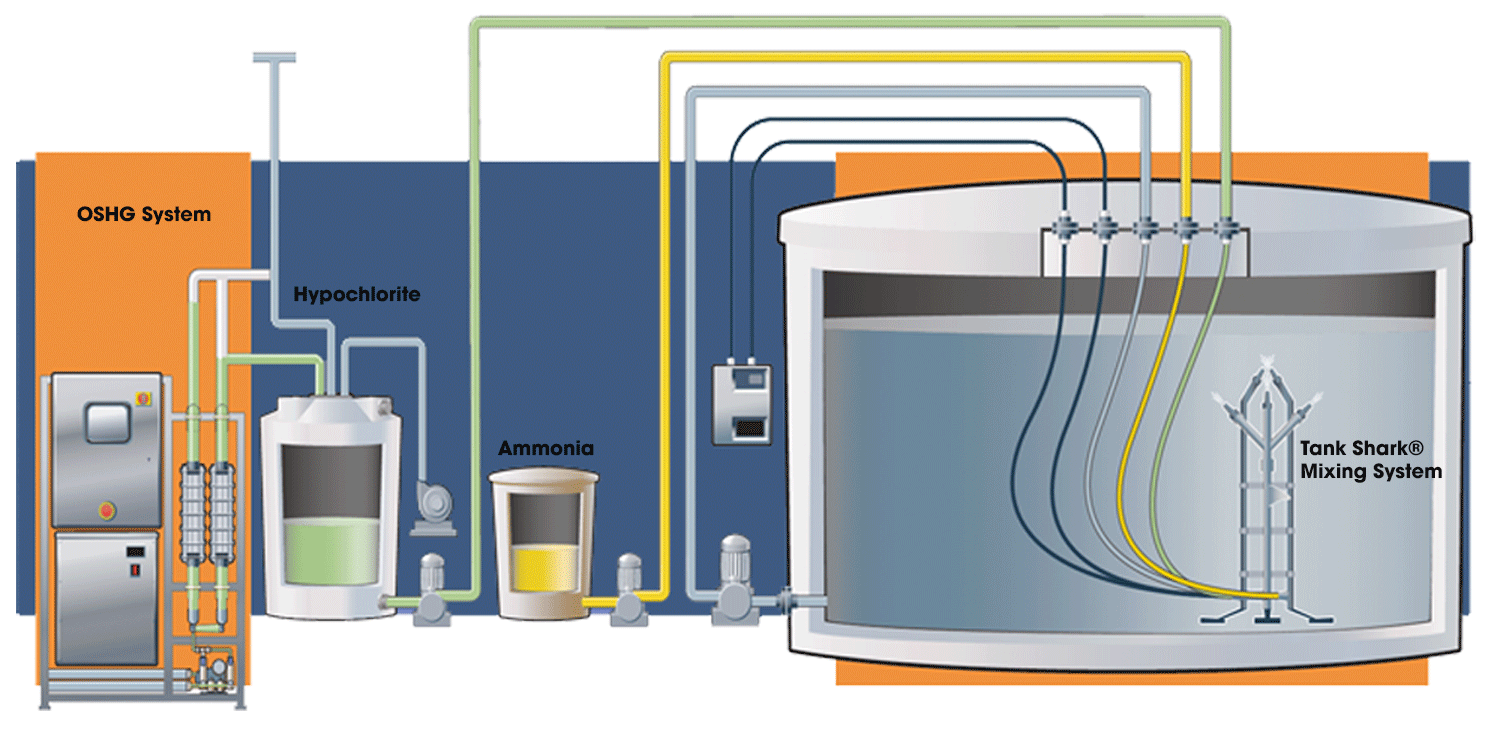

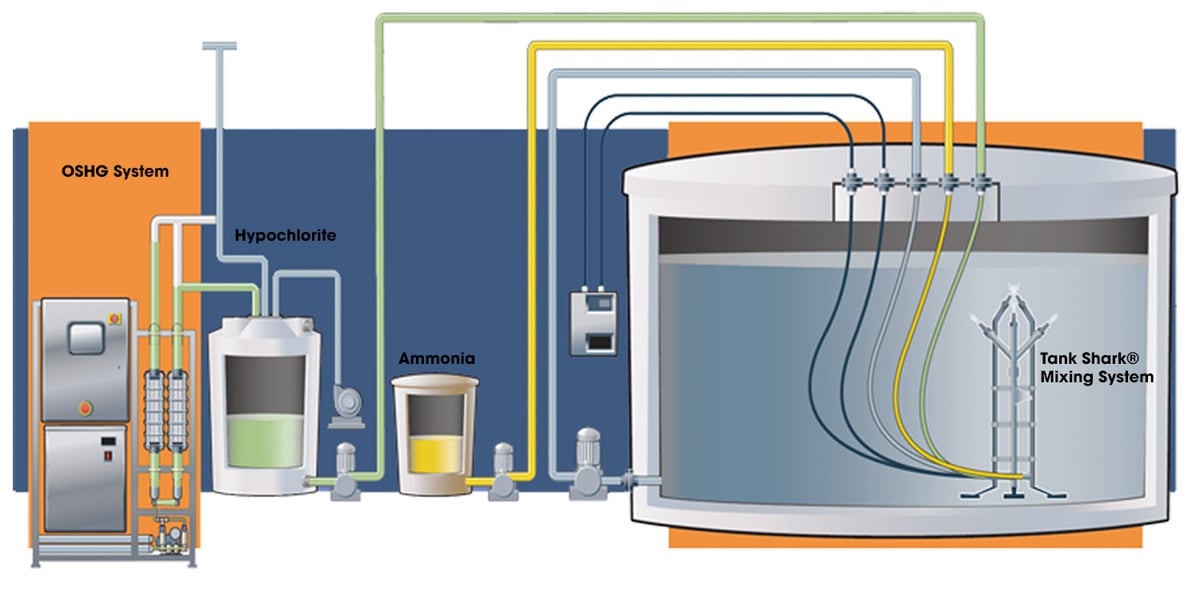

System Overview

How Monoclor® RCS System Achieves and Maintains Tank Equilibrium

The Monoclor® RCS system utilizes a powerful active mixer to rapidly blend disinfectant into the entire tank volume. The Monoclor® RCS system then samples the homogenized water and determines the appropriate chemical dosing strategy based on the disinfectant levels present in the reservoir. By dosing the right chemical at the right time into a completely mixed tank, the Monoclor® RCS system quickly reaches and maintains the desired residual set‐point.

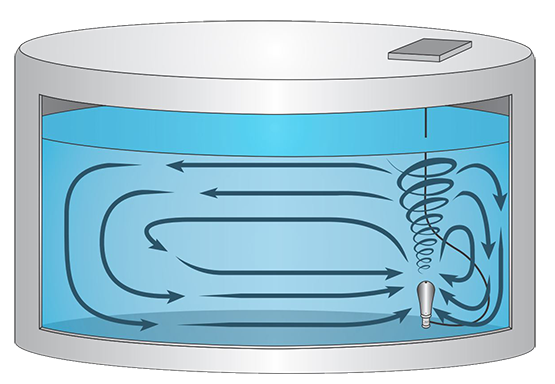

How do PAX Mixers transfer energy leading to homogeneous tank conditions?

PAX mixers transfer motive energy to the mass of water in the reservoir, placing it in motion and ensuring a fully homogeneous condition.

In addition to removing temperature stratification which can hinder consistent disinfectant residual distribution, a fully mixed tank ensures accurate process feedback control in the dynamic environment of a water storage tank.

Chemical injection occurs in the high energy mixing zone allowing for complete mixing and distribution of the applied chemicals.

How Chlorine Boosting and Chloramine Formation Work

If the disinfectant residual drops below a predetermined set point, chlorine only or ammonia is dosed into the reservoir. A Patented algorithm assesses the position of the homogeneous tank chemistry on the breakpoint curve and makes the correct dosing decisions. The Monoclor® RCS process is completely compatible with gas chlorine, bulk hypochlorite and on-site generated sodium hypochlorite. When chloramine delivery is a requirement, liquid ammonium sulphate (LAS) is the feedstock of choice.

Breakpoint Curve

.png?width=303&height=244&name=Residual%20Breaking%20point%20Curve%20(002).png)

The Chemlocker® System

The Chemlocker® system includes a sophisticated real‐time analytical tool that collects and transmits tank sample data (pH, total chlorine and ORP) to enable timely operator intervention – before an emergency occurs. Once an operator decides that tank boosting is desired, the chemical reagents are introduced into the tank via a convenient venturi driven hose connection at the Chemlocker® panel. Powerful tank mixing ensures that the chemical reagents are immediately mixed to start boosting the tank residual level.

The Chemlocker® Reservoir Dosing Station provides operators and water quality professionals with a simple water quality management tool that can aid disinfectant residual management by providing both reservoir residual level assessment and chemical dosing of hypochlorite and or ammonia to reassert control to a free-chlorine or a chloramine disinfectant regime.

Total Chlorine Sampling and Analysis

- An integrated total chlorine analyzer provides dynamic tank residual analysis based on real-time sampling from the tank itself.

- Data availability for the overall network SCADA system.

Chemical Feed

- Simple eductor system for precise chemical injection of both ammonia (in the case of chloramine boosting) and hypochlorite (chlorine).

- A booster pump is optional where a high pressure water source is unavailable on-site.

- The analog flow information from the tank mixer is available locally at the Chemlocker® panel and also via SCADA for remote monitoring. This flow information provides vital feedback to the operator so as to preclude the possibility of chemical addition without proper simultaneous mixing and dispersion.

Benefits of Monoclor® RCS

Powerful Mixing for Rapid Disinfectant Homogenization

Integrates with Liquid, Gas, or OSHG

Real-Time Sampling and Analysis

Data Logging and Remote Monitoring

Safe Introduction of Chemicals

Mobile Systems Available for Disaster Preparedness

Featured Installations

The Colony

Goal: Reduce the complexity of managing multiple water sources, maintain disinfectant residual levels and reduce costly flushing.

Solution: A Monoclor® RCS system featuring and continuous on-line water analysis using a smart control system

City of Milpitas

Goal: Manage disinfectant residual levels without the need for frequent testing, manual boosting and tank cycling

Solution: A Monoclor® RCS system and a Microclor® On-Site Hypochlorite Generation System

City of DeSoto

Goal: Reduce flushing; maintain acceptable disinfectant residual levels

Solution: A Monoclor® RCS system, tank mixing and continuous on-line water analysis using a smart control system

"We used to struggle with water age in this part of our system, but the RCS has made our water age problems essentially go bye-bye.

It’s like a little treatment plant. We’re controlling the water."

Checks All The Boxes

Targeted disinfectant control without a treatment plant upgrade.

Built-in multi-operational fail safes, alarm redundancy.

Quick reaction to imported water upsets quality changes.

Reduces flushing and nitrification events.

Ideal for retail systems without treatment capabilities.

Provides dosing option for wholesalers with problematic zones.

"Ever since we installed the Monoclor® RCS, I have much more confidence that we can maintain a meaningful residual throughout our distribution system."

Let's get the conversation started

Tell us a little bit about you and the information you’re looking for and we'll send you information by email about the topics you are interested in. Check the box to have a cleanwater1 expert contact you within one business day.

Additional Resources

Learn At Your Pace

By subscribing to our learning track, you will receive emails featuring videos, webinar invites, informative articles and more.

View Our Online Library

Featuring brochures, case studies, data sheets and more. Filter by product category, brand, location, use case or document type.

Connect With Us

Contact a member of our team using our online form, by email or give us a call. We look forward to speaking with you.