VeloBlend

Our Liquid Polymer Systems

VeloBlend Liquid Polymer Activation Systems

Since VeloBlend's introduction, polymer blending has changed forever — so much so that our unique VeloBlend mixing technology was granted a U.S. patent. The VeloBlend's hybrid polymer activation technology combines the reliability of non-mechanical blending with controllable, variable-speed hydro-mechanical mixing energy. This allows for precise control of mixing conditions, allowing you to optimize the performance of any polymer available, while not relying on water pressure.

While the rest of the polymer equipment industry was engaged in a mechanical versus nonmechanical system debate, VeloDyne developed the next generation of advanced polymer activation technologies, a hybrid of the two approaches..

The Science of Efficient Polymer Activation

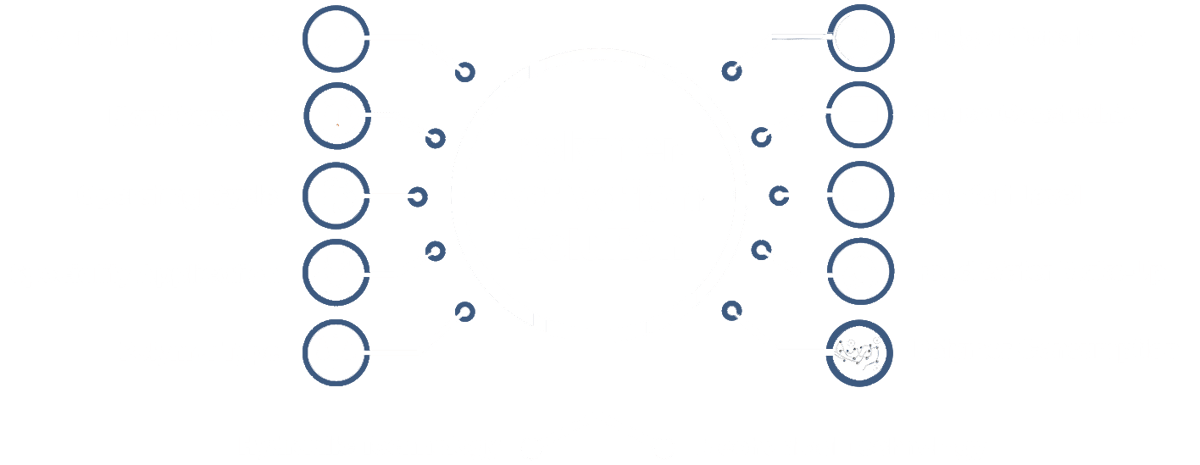

High Energy at MOIW

+

Transition to Low-Energy "Quiescent Zone"

+

=

Fully Activated Polymer Solution at Desired Concentration

Features

-

Patented hybrid polymer Activation Technology

-

Stainless-steel mixing chamber

-

Progressive cavity neat polymer pump (other pump options available)

-

Loss of polymer and water flow alarms

-

Mechanical relay logic or PLC control systems

-

Stainless-steel skid

-

Optional automatic water control (ratio control of polymer and water)

Technical Data

- Progressive cavity pump range from 0.025 to 24 GPH neat polymer

- Dilution water from 0.2 to 40 GPM

- Mechanical relay logic or PLC control (see PDF brochure for options)

VeloBlend Series VM8

Features

- Patented hybrid polymer Activation Technology

- Stainless-steel mixing chamber

- Progressive cavity neat polymer pump (other pump options available)

- Loss of polymer and water flow alarms

- Mechanical relay logic or PLC control systems

- Stainless-steel skid

- Optional automatic water control (ratio control of polymer and water)es

Technical Data

- Progressive cavity pump range from 1.5 to 60 GPH neat polymer

- Dilution water from 10 to 100 GPM

- Mechanical relay logic or PLC control (see PDF brochure for options)s

Features

- Patented hybrid polymer Activation Technology

- Stainless-steel mixing chamber

- Progressive cavity neat polymer pump (other pump options available)

- Loss of polymer and water flow alarms

- Mechanical relay logic or PLC control systems

- Stainless-steel skid

- Optional automatic water control (ratio control of polymer and water)e

Technical Data

- Progressive cavity pump range from 4.5 to 120 GPH neat polymer

- Dilution water from 15 to 200 GPM

- Mechanical relay logic or PLC control (see PDF brochure for options)

Features

- Patented hybrid polymer Activation Technology

- Stainless-steel mixing chamber

- Progressive cavity neat polymer pump (other pump options available)

- Loss of polymer and water flow alarms

- Mechanical relay logic or PLC control systems

- Stainless-steel skid

- Optional automatic water control (ratio control of polymer and water)e

Technical Data

- Progressive Cavity Pump Range: 12 to 360 GPH

- Dilution water Range: 40 to 600 GPM

- Mechanical relay logic or PLC control (see PDF brochure for options)

Which Technology is Right for You?

Our team of trained experts can help determine the best technology for your application. Because we are not limited to one technology, you can feel confident knowing we’re committed to finding the system that meets your process objectives.

Let's get the conversation started

Tell us a little bit about you and the information you’re looking for and we'll send you information by email about the topics you are interested in. Check the box to have a cleanwater1 expert contact you within one business day.

Additional Resources

Learn At Your Pace

By subscribing to our learning track, you will receive emails featuring videos, webinar invites, informative articles and more.

View Our Online Library

Featuring brochures, case studies, data sheets and more. Filter by product category, brand, location, use case or document type.

Connect With Us

Contact a member of our team using our online form, by email or give us a call. We look forward to speaking with you.