PAX TRS™

PAX TRS™, A Trihalomethane Removal System

The Ideal Choice for THM Reduction and Removal

Trihalomethanes (THMs) are chemical compounds that form when natural organic matter in water reacts with chlorine during the disinfection process. THMs are a suspected carcinogen and regulated in many countries. Exceedences of the Maximum Contaminant Level (MCL) for THMs are among the most common violations of the EPA Stage II DBP rule in the United States.

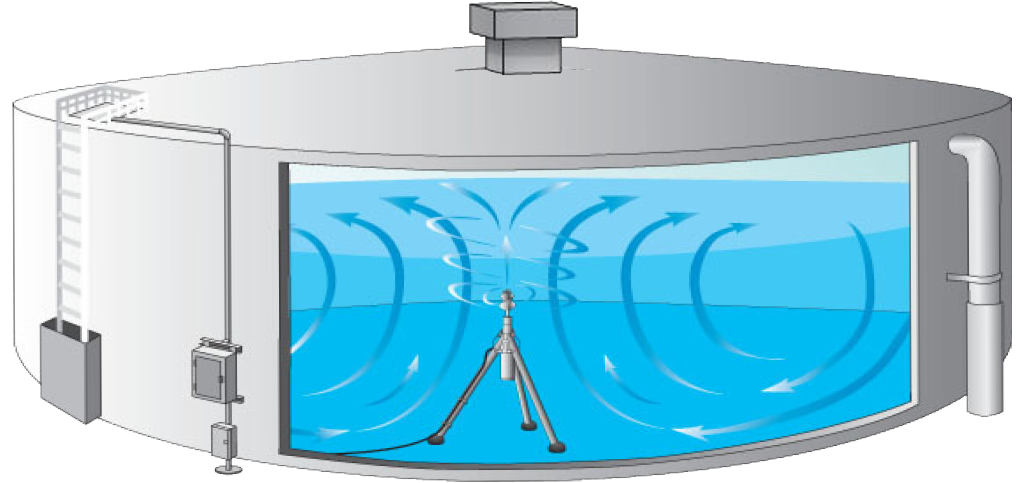

Unlike most THM removal technologies that involve large-scale changes to the water treatment plant, the PAX TRS™ (Trihalomethane Removal System) is a custom-designed, energy-optimized system of mixers, aerators and ventilation systems which that converts ordinary water storage tanks into water treatment systems.

By implementing a thoughtful combination of sub‐systems that include active headspace ventilation, PAX Mixers for powerful tank mixing, NSF certified surface aerators and Neptune-Toolbox modeling, PAX TRS™ systems have become the leading choice for utilities and engineers that require guaranteed levels of THM reduction in water storage tanks.

Neptune-Toolbox™ is a modeling tool that looks at tank hydraulics, mass transfer, THM loading, THM diffusion rates and energy consumption to develop the optimal system design for a particular tank.

A PAX Mixer is used to continually move THM-concentrated water to the surface where THMs are volatilized and evacuated by active headspace ventilation.

Key Elements of a Successful THM Removal System

Successful tank-based trihalomethane (THMs) aeration requires three elements:

- A well-mixed tank

- A continual supply of fresh air circulating through the tank headspace

- Enough water surface area to achieve the desired level of removal

So while a PAX Mixer is used to continually move THM-concentrated water to the surface where THMs are volatilized, active headspace ventilation is used to remove the saturated air out of the tank.

Our Secret to Cost-Efficient THM Removal: Ventilation, Active Mixing and Modeling

Headspace ventilation devices are critical to ensure that THMs which volatilize into the tank’s headspace are efficiently removed from the tank.

PAX Mixers assist in removing THMs by continually pushing water up to the surface where the THMs can evaporate out of the water and into the headspace of the tank.

Modeling enables our engineers to use tank volume, fill/drain cycle, geometry and THM speciation to derive an optimal mixer energy input. With this information, our engineers will recommend available mixer form factors, aeration devices and ventilation combinations to ensure optimal THM removal.

The Neptune-Toolbox™ Model

Using water storage assets as a starting place to effect the removal of THMs from water distribution networks makes sense from both a hydraulic and chemical engineering perspective. Each water distribution network will experience unique THM formation characteristics which dictate the level of THM formation through the network over time.

Water characteristics such as water age, temperature, disinfectant concentration and disinfectant residual type all influence the formation of THMs. As a result, we have developed a robust model called Neptune-Toolbox, that considers the factors that contribute to THM formation in water systems and helps derive an engineered THM removal solution that meets client needs for THM removal.

Energy consumption is often the most significant factor in a system’s total cost over a period of years. The Neptune-Toolbox™ model determines whether the energy consumption tradeoff is worth the initial equipment cost. It can provide a series of equipment recommendations based on client circumstances and requirements.

The Neptune-Toolbox™ design tool is backed by the industry’s strongest guarantee for THM removal products ‐> 100% success rate in achieving removal targets!

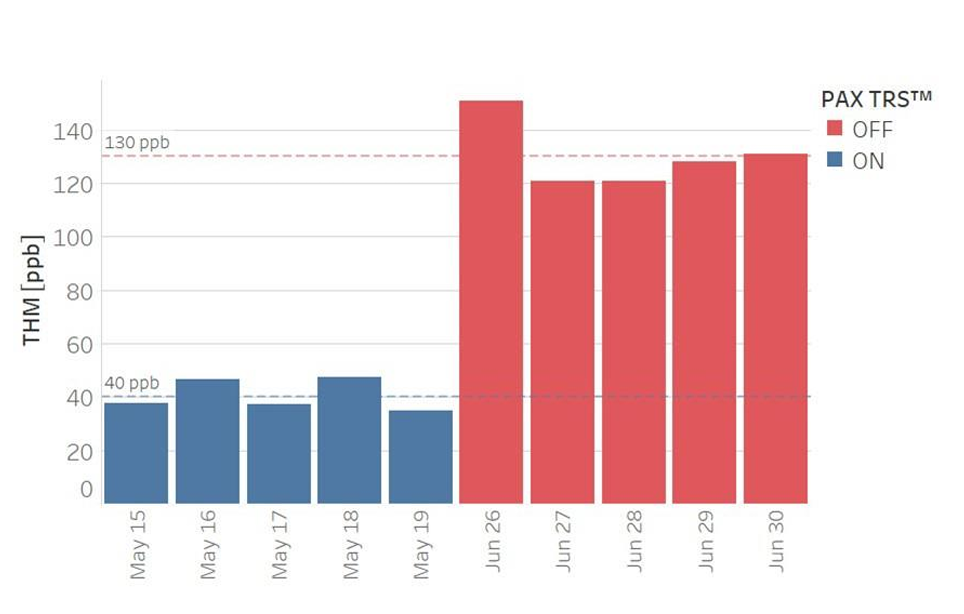

"We are seeing excellent results from the system. We are seeing THM levels 40-70% lower leaving our tank than those coming in."

Product Information

System Features

- Guaranteed THM removal rates

- VFD controlled tank headspace ventilation equipment that is tuned for each tank

- Aggressive tank mixers for removing THM concentration gradients and optimizing THM removal efficiency

- Surface aeration and spray aeration options for additional mass transfer where high levels of THM removal are required

- Sophisticated tank modeling and process control for smart energy management

- NSF61 approved materials

- Active headspace ventilation creates ideal conditions to volatilize THMs

- Robust equipment including non-clogging aeration nozzles and low maintinance surface aerators

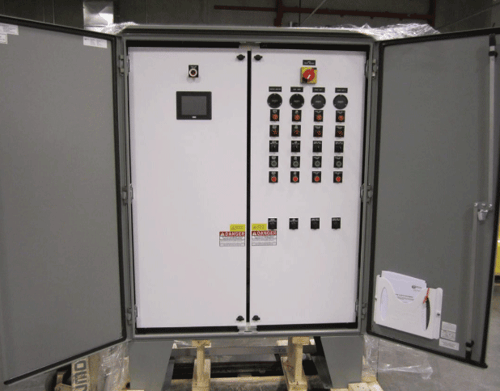

Overview of Control Panel

The Integrated control panel brings the controls for aeration, air handling, and mixing systems into a single, high quality control panel that meets the specific and unique standards of each customer.

The Integrated control panel brings the controls for aeration, air handling, and mixing systems into a single, high quality control panel that meets the specific and unique standards of each customer.

From a bare bones set of motor starters, to custom programed PLC based panels, we have the experience and expertise to understand your controls requirements and deliver plug and play panels that minimize field wring.

With our standard offering featuring Allen Bradley components, we can provide the right level of customization. Options include:

PLC Manufacturer: Allen Bradley, Siemens, GE, IDEC

Enclosure Type: NEMA 3R, NEMA 4X, Deadpanels, Sunshades

Active Feedback Control: Integrate an on-line THM sensor to continually monitor THM concentration in the tank effluent, and save energy and run time by turning off equipment when THM treatment is not needed.

Customized Designs

When it comes to selecting the right THM removal system for your tank, custom design is key. Optimizing system design is critical for predicting and achieving THM removal rates, minimizing energy requirements and calculating long-term operating costs.

We partner directly with municipalities and engineers to diagnose THM formation and perform a system-wide treatment analysis. This data combined with our proprietary design and performance modeling software, enables us to create in-tank aeration systems that are cost-effective and energy-optimized.

The result is right-sized THM removal technology for your specific tank’s needs.

"The PAX TRS™ system was easy to install and performed well by delivering a level of THM removal that helps ensure our system compliance."

Featured Installations

Western Water

Goal: Utilize aeration in the distribution system to mitigate THM levels. Their goal was 30% THM removal in their Rosslyne Tank.

Outcome: The PAX TRS™ THM Removal System removed 36% of THMs after the first test. It only took a couple of days for PAX TRS™ to achieve its lowest levels of THMs. This lower level remained consistent. PAX TRS™, accompanied by PAX mixing technology, enabled Western Water to run the equipment 24/7.

Suisun Solano

Goal: THM removal in their 2MG tank

Solution: PAX TRS™THM Removal System, a PAX PWM-400 tank mixer, a rooftop ventilation unit and 4 surface aerators

San Luis Obispo

Goal: Manage THM formation as water age increases. Stay below the 80 parts per billion (ppb) threshold set by the US EPA. Achieve a 40% THM reduction.

Solution: PAX TRS™THM Removal System and a PAX PWM-500 tank mixer

Benefits of PAX TRS™

Custom-designed system for precise THM removal reates

Energy-optimized for low operating cost

Scalable designs for tanks 50,000 gallons to 50 million gallons

Let's get the conversation started

Tell us a little bit about you and the information you’re looking for and we'll send you information by email about the topics you are interested in. Check the box to have a cleanwater1 expert contact you within one business day.

Additional Resources

Learn At Your Pace

By subscribing to our learning track, you will receive emails featuring videos, webinar invites, informative articles and more.

View Our Online Library

Featuring brochures, case studies, data sheets and more. Filter by product category, brand, location, use case or document type.

Connect With Us

Contact a member of our team using our online form, by email or give us a call. We look forward to speaking with you.