Dry Polymer Activation

Dry Polymer Activation for Wastewater Treatment

How it Works

Dry polymer activation is a process used in wastewater treatment to enhance the flocculation and sedimentation of suspended solids in wastewater. Dry polymers are long-chain molecules that can help to bind together the small particles of suspended solids in wastewater and form larger, heavier flocs that can settle more easily.

In dry polymer activation, the polymer is first mixed with a small amount of water to form a concentrated solution. The concentrated solution is then added to the wastewater and mixed thoroughly to ensure that it is evenly distributed throughout the wastewater. The polymer molecules then begin to interact with the suspended solids in the wastewater, causing them to coagulate and form larger flocs that are easier to remove from the wastewater.

Creating the Ideal Environment for Superior Mixing

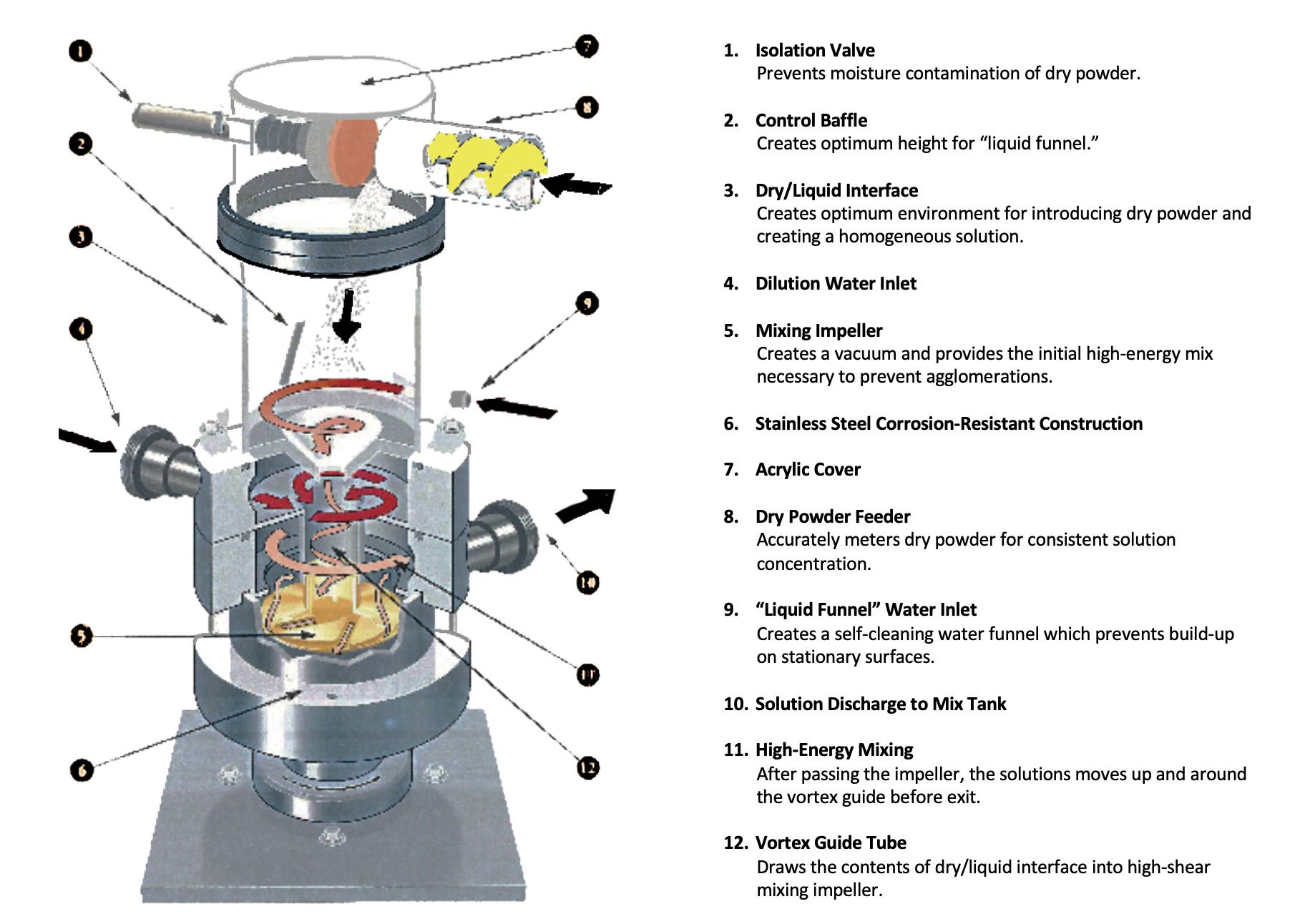

To create the ideal environment for the first stage of dry polymer dissolution, crucial initial wetting occurs in the DD4 disperser. Here, polymer and water are subjected to high energy created by mechanical mixing. The dry polymer is accurately metered into the high-energy mix chamber and is properly activated with water. After brief exposure, the solution exits the high-energy disperser. The point of initial polymer / water contact is visible to the operator through a clear, acrylic interface.

Creating the ideal environment for dry polymer activation.

The Science of Efficient Polymer Activation

High Energy at MOIW

+

Transition to Low-Energy "Quiescent Zone"

+

=

Fully Activated Polymer Solution at Desired Concentration

Low-Energy Tanks Create Uniformity

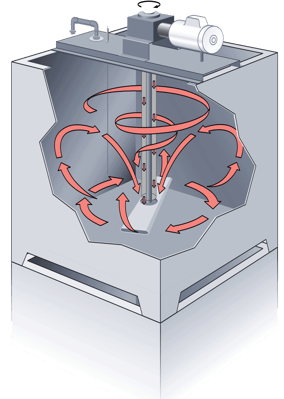

Most polymer mix tanks are not uniform in their mixing energy. Agglomerations form in the portions of the tank that receive the least mixing energy, while polymer chains are broken up at the tip of the rotating mixing blade.

In contrast, our dry polymer tank is specifically designed to be fully uniform in mixing intensity. The rotating impeller is a “hollow wing,” the length of which is over half the width of the tank. The hydraulics of the system make the impeller act like a pump, continuously moving the solution vertically as well as horizontally.

The square tank design further contributes to uniformity of the mixing energy, eliminating the potential for a damaging vortex. The result is minimal agglomerations and minimal broken polymer chains - minimal waste. Polymer costs are reduced and performance is improved.

Low-Energy Mix Tank from the Polyblend® DP Series.

Optimize For Your Situation with Dry Polymer

The activation of the dry polymer can be achieved through a variety of means, including mechanical mixing, agitation, or the addition of other chemicals such as coagulants or flocculants.

The activation process is typically optimized for each specific application to ensure that the polymer is activated in the most effective way possible to achieve the desired results for your water or wastewater application.

Dry polymer has a shelf life of over 3 years if unopened and properly stored.

Our Dry Polymer Activation Solutions

Polyblend® Dry Polymer Activation

The Polyblend® Dry Polymer Hydraulically actuated tubular diaphragm pumps and skid Systems are ideal for feeding slurries, high-viscosity fluids and corrosive liquids.

Dynajet™ Pneumatic System

The Dynajet™ technology uses a blower-induced pneumatic conveyance system to transfer up to 12 lbs of polymer per minute from the volumetric feeder to the wetting head.

HydraMax™ Dry Polymer Preperation Systems

The ProBatch™ direct wetting bowl technology is recommended for applications up to 5#/hour of dry polymer. The HydraMax™ shower type wetting technology is recommended for applications up to 2000# per hour.

Let's get the conversation started

Tell us a little bit about you and the information you’re looking for and we'll send you information by email about the topics you are interested in. Check the box to have a cleanwater1 expert contact you within one business day.

Additional Resources

Learn At Your Pace

By subscribing to our learning track, you will receive emails featuring videos, webinar invites, informative articles and more.

View Our Online Library

Featuring brochures, case studies, data sheets and more. Filter by product category, brand, location, use case or document type.

Connect With Us

Contact a member of our team using our online form, by email or give us a call. We look forward to speaking with you.