Encore® and Chemtube®

Encore® Chemical Metering Pumps

Reliable. Accurate. Versatile.

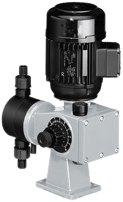

For decades, Encore® chemical metering pumps have provided operators with reliable, accurate and versatile pumping solutions for all types of liquid and slurry dosing.

cleanwater1's chemical metering pump packages are designed to meet the needs of virtually any industrial or municipal liquid chemical feed application. They are completely assembled systems offering the features and flexibility required for accurate chemical metering with the benefit of easy installation, start-up, operation and maintenance with a "plug-and-play" approach.

Built to Last

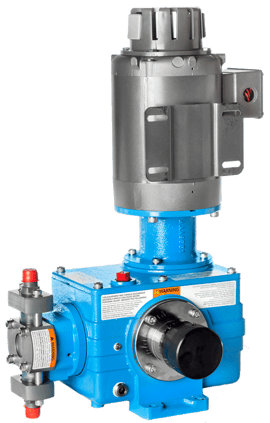

For decades, Encore®700 metering pumps have been the rugged, reliable and accurate metering choice of plant operators and designers. With the Encore®700 pump line dosing liquid or slurry at operating capacities of 0.31 gph to 660 gph and at pressures up to 175 psi, the precision of the non‐loss‐of-motion pumping profile is an added benefit.

In a world where “throwaway” metering pumps have become acceptable, it is commonplace to observe the Encore® 700 flagship pump operating in demanding chemical feed environments for decades.

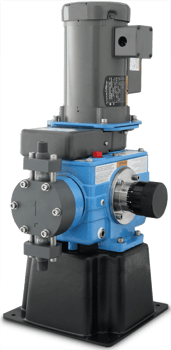

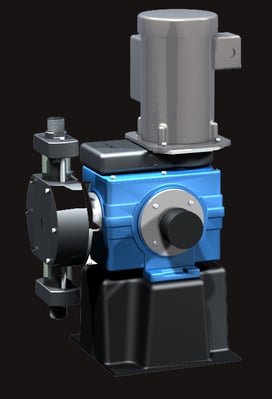

Displayed here is the Encore® 700 metering pump, recognized throughout the industry for its longevity, reliability and accuracy. Many models are also certified to NSF/ANSI 61 standards for use in drinking water applications.

A Long History of Reliability, Safety and Accuracy

With over 100 years of liquid feed experience, cleanwater1 continues to be the leader in disinfection and chemical feed systems for potable water, wastewater and industrial process applications.

cleanwater1 products provide safe, reliable and accurate methods for controlling the amount of chemicals added to water sources or processes.

cleanwater1 equipment can be used to accurately dose chemicals ranging from sodium hypochlorite and caustics to viscous polymers and slurries. High performance materials are used in all critical areas to ensure optimum compatibility and long service life.

The complete line of liquid feed equipment offers an extensive range of capacities from 0.09 gph (0.3 lph) to over 660 gph (2,500 lph).

Encore's Many Configurations and Features

Encore® Pumps are available in a variety of types. Variations include those with integrated controls capabilities, including solenoid-driven, mechanically actuated, as well as integrated dosing and controls packaged systems, for municipal and industrial markets.

Encore® motor driven metering pumps use a rugged drive mechanism and composite diaphragm for long life and easy serviceability. Suitable for most chemicals across a wide range of capacities and pressures.

Encore® 700 metering pumps, recognized throughout the industry for their longevity, reliability and accuracy, with several models certified to NSF/ANSI 61 standards for use in drinking water applications.

Encore® 700 Overview

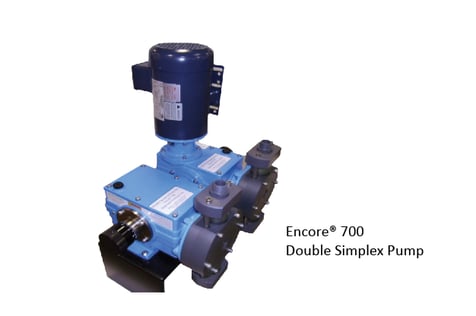

The Encore® 700 Diaphragm Metering Pump is a rugged, heavy-duty mechanical diaphragm metering pump available with six diaphragm sizes and simplex, duplex and double simplex configurations.

-

Simplex Pumps offer a single head design on single gear box with stroke control.

-

Duplex Pumps offer two identical sized heads on single gear box with common stroke length control, and a direct drive arrangement.

-

Double Simplex Pumps offer two heads with two gear boxes, each with independent stroke length control, and a common motor.

The Encore® 700 pump is engineered to handle industrial and municipal metering applications in water and wastewater treatment, swimming pools, food processing, chemical processing, brewing and distillation, and agriculture.

Features

- Handles capacities to 634 gph (2,400 l/h), back pressures to 175 psi (12 bar).

- Non-loss-motion (amplitude modulation) stroke adjust mechanism renders unrivaled efficiency, longevity and reliability.

- Choice of two field convertible drives-direct coupled or pulley coupled.

- Precision engineered liquid ends meter mild solutions, aggressive chemicals, high viscosity polymers and slurries with far greater efficiency than conventional liquid ends.

- Clear PVC cartridge valves for fast, fool proof service with no piping disturbances and built-in visual indication of operation.

- Premium diaphragm design ensures high metering accuracy, even at varying discharge pressures.

Benefits

- Combines robustness of hydraulic diaphragm drives with the unparalleled economy, simplicity and serviceability of mechanical diaphragm liquid ends.

- Efficient, reliable and smooth discharge pattern through the use of a variable non-loss motion eccentric stroke adjustment.

- High metering accuracy even at varying discharge pressures.

- Choice of direct coupled or pulley driven, for an additional 4:1 turndown on stroke frequency.

- Fast and easy service of valve assemblies without disturbing the suction and discharge piping.

- Visual indication of operation with standard clear PVC valves housing.

- Choice of configurations: Simplex, Duplex and Double Simplex.

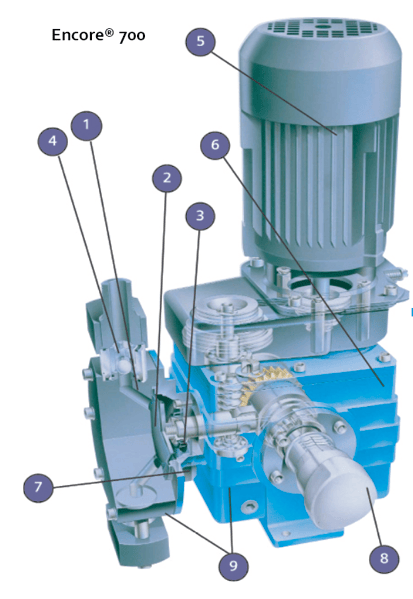

Product Diagram of the Encore® 700

Pump Head

Diaphragm

Bellow Seal

A secondary diaphragm seal completely separates the pump head from the drive unit. This double diaphragm isolating design eliminates the risk of cross-contaminating gearbox lubricant and process fluid.

Cartridge Valves

High precision guided, ball and seat, clear PVC cartridge valves are available to provide built-in sight flow indication and fast, foolproof service. The proven design includes wide flow paths and four-point guides to control ball rise and assure proper seating. The valve housing is compression-sealed to the pump head and pipe connectors by O-rings and is easily removed for the service or replacement without disturbing the external piping.

Motor

Available with standard induction, variable speed, or inverter duty motors for wider operating ranges and automatic process control.

Gear Box

This proven robust mechanical assembly features liberal use of heavy-duty parts, including an epoxy-painted cast iron gearbox for superior corrosion resistance, stainless steel fasteners, load-absorbing tapered roller bearings, robust gears, and steel and nodular iron drive components.

Leak Detector

An optional diaphragm leak detection system senses the early stages of diaphragm failure. The system consists of a solid-state, electro-optic sensor that mounts to the liquid end and a control box. This box, which can be mounted at the pump, or up to 100 ft. (30m) away, can monitor two liquid ends. LED’s and a relay provide both local and remote indication of failure.

Stroke Length Adjustment

Obtain precise and highly repeatable feed rate settings with a 10-turn, micrometer-type stroke length adjuster. A percent scale and vernier indicate stroke length in 0.25% increments. Feed rate is infinitely adjustable from 0 to 100%. Optional automatic capacity control via stroke length is also available.

Drive Configuration

Proven, reliable drive and control mechanism with precision liquid end design offer superior metering and process control performance.

Available in a direct drive configuration or a pulley coupled arrangement for additional 4:1 turndown on stroke frequency.

"For 13 years, our Encore® 700 pumps have been running perfectly. We are very pleased. This is the best pump I’ve ever used! We keep them maintained and they just seem to run forever."

Encore® & Chemtube® Skid System

The Encore® Pump Skid system is designed to meet the needs of virtually any industrial or municipal liquid chemical feed application. It is a completely assembled system, offering the features and flexibility required for accurate chemical metering with the benefit of easy installation, start-up, operation and maintenance.

The Encore® Pump Skid system is designed to meet the needs of virtually any industrial or municipal liquid chemical feed application. It is a completely assembled system, offering the features and flexibility required for accurate chemical metering with the benefit of easy installation, start-up, operation and maintenance.Features

- Compact Design Utilizes Minimal Floor Space

- Factory-Tested, Economical to install

- Wide Choice of Capabilities for Customized Arrangements

- Less Costly Service and Repair

- Add on Capability

EZ Drum Shelf

place with the EZ Drum Shelf. The EZ Drum Shelf is designed to secure a metering pump atop a metal or plastic 55-gallon drum. The unit, constructed of 1/2 inch PVC, prevents pumps from tipping over. The semicircular shelf has lift handles on each side, allowing the operator to quickly and safely move the pump and tubing assembly to a new drum.

place with the EZ Drum Shelf. The EZ Drum Shelf is designed to secure a metering pump atop a metal or plastic 55-gallon drum. The unit, constructed of 1/2 inch PVC, prevents pumps from tipping over. The semicircular shelf has lift handles on each side, allowing the operator to quickly and safely move the pump and tubing assembly to a new drum.The EZ Drum Shelf is a perfect complement to LMI's drum safety wand (Model 26783 for plastic drums with 2" buttress threads). The drum safety wand helps prevent curling of suction tubing, keeps the foot valve at the bottom of the tank and protects the operator from swinging tubing.

Features & Benefits

- 1/2 inch PVC Construction

- 4 PCV legs

- Pre-drilled mounting holes for LMI's A, B, C and P series pumps

- Can accommodate other makes of metering pumps

- Stainless mounting hardware included

- Built-in lift handles

- Rugged, great fro industrial settings

- East to install

- Provides stability

- Holds a variety of pump sizes

- Portable, easy to move from drum to drum

EZ1 Pump Skid System

The EZ1 Pump System is a skid-mounted chemical metering system designed for maximum reliability and convenience. The EZ1 package utilizes LMI pumps providing a broad range of capacities and flexibility to handle a wide range of applications.

EZ1 Systems are typically used in water treatment programs to dose proper amounts of inhibitors, dispersants, biocides, as well as pH control chemicals and oxidants. The EZ1 is very easy to install, operate and maintain. This system comes complete and ready for service upon delivery.

Popular accessories are added as applications require. Typical packages include timers, controllers, and instrumentation to allow the unit to be controlled from an external process signal.

Features

- Safe, efficient LMI metering pumps

- Pre-plumbed calibration kit

- Structurally rigid fiberglass base

- Accessory Options: Timer, pH Controllers, High Resolution Redox® Controller, Recorders, Pump Speed Controller, Pulse Counter, Feed Verification, Visual / Audio Alarms, Stainless Steel Base

- Ready-to-install as delivered

- Easy to set, easy to use

- Economical

- Portable

- Proven reliable and rugged

- Can accommodate a number of accessories

EZ2 Dual Pump Skid System

The EZ2 Dual Pump Skid System is a skid-mounted chemical metering system designed to feed either one or two chemicals together or separately. The EZ2 package utilizes LMI pumps providing a broad range of capacities and flexibility to handle a wide range of applications. EZ2 Systems are typically used in water treatment programs to dose proper amounts of inhibitors, dispersants, biocides, as well as pH control chemicals and oxidants.

This system is ideal for dual biocide programs, especially when accessorized with a two-channel timer, and is very effective in administering liquid chlorine/bromine programs when the Strantrol® 890 option is selected. The EZ2 is very easy to install, operate and maintain. This system comes complete with a standard calibration kit and is ready for service upon delivery.

Popular accessories are added as applications require. Typical packages include timers, controllers, and instrumentation to allow the unit to be controlled from an external process signal.

Features

- Safe, efficient LMI metering pumps

- Pre-plumbed calibration kit

- Stainless steel base

- Accessory Options: Timer, pH Controllers, High Resolution Redox®controller, Recorders, Pump Speed Controller, Pulse Counter, Feed Verification, Visual / Audio Alarms, Stainless Steel Base

Benefits

- Ready-to-install as delivered

- Easy to set, easy to use

- Economical

- Portable

- Proven reliable and rugged

- Can accommodate a number of accessories

Control Panels

The metering pump control panel is specifically engineered and designed for control of Encore® and Chemtube® metering pumps.

Encore® and Chemtube® Metering Pump Control Panels

The cleanwater1 metering pump control panel is specifically engineered and designed for control of Encore® and Chemtube® metering pumps. the panel utilizes a variable speed controller, which controls the speed of the pump's motor and uses state-of-the-art technology.

panel is specifically engineered and designed for control of Encore® and Chemtube® metering pumps. the panel utilizes a variable speed controller, which controls the speed of the pump's motor and uses state-of-the-art technology.

The enclosure is NEMA 4X rated with a continuous-hinged gasketed door. It includes indication of status via pilot lights and a digital motor speed indicator, as well as normally closed contact for remote indication of pump run or failure. A standard disconnect switch is provided.

Features

- Local or remote control

- Choice of VFD or SCR configuration

- Standard NEMA 4X fiberglass enclosure

- Choice of single or dual pump controls

- User friendly controls

Hydraulically Actuated Tubular Diaphragm Pumps

Cast-iron design; ideal for feeding slurries and high-viscosity fluids and corrosive liquids.

Other Pumps in the Encore Family

Encore® E Solenoid Pump

The Encore® E (electronic) solenoid pump is a good value choice for simple and continuous dosing applications. The Encore® EM/ED/EK/EP model is available in seven capacity ranges, up to 3.96 gph.

The Encore® E (electronic) solenoid pump is a good value choice for simple and continuous dosing applications. The Encore® EM/ED/EK/EP model is available in seven capacity ranges, up to 3.96 gph.

The Encore® EA model is available in three capacity ranges, up to 40 gph. The pump is certified for compliance to UL and CSA standards.

Encore® ME Mechanical Motor-Driven Pump

The manually controlled Encore® ME and the microprocessor-based Encore® MB models are available in eleven capacity ranges, up to 92 gph.

The manually controlled Encore® ME and the microprocessor-based Encore® MB models are available in eleven capacity ranges, up to 92 gph.

The Encore® MB model’s integrated speed control provides up to 1400:1 turndown. The pump is certified for compliance to UL and CSA standards.

Stepper Motor Pump

The compact Encore SK/SM/SP stepper motor pumps, coupled with an intelligent drive concept, combines the significant advantages of a solenoid driven pump with the precision of a mechanical motor-driven pump.

The compact Encore SK/SM/SP stepper motor pumps, coupled with an intelligent drive concept, combines the significant advantages of a solenoid driven pump with the precision of a mechanical motor-driven pump.

They are available in four capacities, up to 5.20 gph and up to 232 psi. Discharge and suction strokes can be controlled at different speeds. This produces a constant supply stream, which results in low-pulsation dosing.

Chemical Metering Pump Skid

The pre-wired, plumbed and tested skid can be easily installed and commissioned within a short period of time, reducing the need for extensive on-site prep work.

cleanwater1 can supply a complete line of hydraulic accessories, as well as custom designed skid mounted pump and dosing packages to suit virtually any municipal or industrial application.

The turnkey skid system saves time and labor costs, allowing quick implementation of the equipment into the plant operation.

Encore® 700 Plunger Pump

The Encore® 700 Plunger Pump utilizes the proven Encore® 700 gearbox to meet high pressure applications.

The Encore® 700 Plunger Pump utilizes the proven Encore® 700 gearbox to meet high pressure applications.

It is available in four capacities, up to 38 gph and up to 2900 psi.

Get the Perfect Pump for Your Application

With cleanwater1, you do not have to compromise on a marginal liquid feed and controls technology for a particular application. Instead, you can choose from multiple technologies to match the best pump to your application.

A rugged, heavy duty mechanical diaphragm metering pump available with six diaphragm sizes and double simplex capability to handle capacities up to 660 gph and backpressure to 175 psi. Other benefits:

- Non-Loss motion stroke adjust mechanism for reliability and longevity.

- Available in either a direct drive configuration or a pulley coupled arrangement for additional 4:1 turndown on stroke frequency.

- Manual control or control via an automatic stroke length positioner or variable speed drive or both

- Optional diaphragm leak detector.

Featured Installations

Upper Deerfield

Goal: Implement a treatment process at the water plant that could pump a heavy 12% lime slurry into the finished drinking water to maintain alkalinity. Decrease the occurrence of low pH alarms going off.

Outcome: The Encore®700 had an immediate improvement on performance. The Encore®700 Pump was able to generate up to 50 GPH and deliver 12% slurry efficiently against 75 psi backpressure. Not only could the team rely on the Encore®700 Pump’s reliability and pumping power to deliver up to 50 GPH consistently, the new system maintained a steady pH level and required much less maintenance.

Southern Nevada Water Authority

Goal: Improve the process used to accurately and effectively feed the electrolyzers of their nine on-site hypochlorite generation units. Each unit produced up to 2,000 pounds per day of equivalent chlorine for residual disinfection.

Outcome: The Encore® 700 pumps worked as planned. The flexibility of the Encore® 700 pumps allowed the operation team to manually adjust eccentricity during operation and required fewer parts. SNWA ended up purchasing a total of 9 Encore® 700 Double-Simplex pumps.

Jericho Water District

Goal: JWD struggled with controlling corrosion in their pipes. This had an impact on achieving accurate pressure and water speed. They needed a solution that would address corrosion, operations, maintenance, repairs and costs.

Outcome: The Encore® 700 required far less maintenance compared to JWD’s previous systems, saving the operating team time and reducing operating costs. The Encore® 700 provided reliable and efficient operation with minimal system vibration The Encore® 700 allow the operating team to manually, and smoothly adjust eccentricity during operation. JWD purchased an additional 11 Encore® 700 pumps.

“The Encore® 700 pumps have been working great for us. They’re a lot less maintenance – virtually maintenance-free – and the problems we had with the previous pump just aren’t there with the Encore® 700. We plan to continue converting every pump at all of our wells..”

Let's get the conversation started

Tell us a little bit about you and the information you’re looking for and we'll send you information by email about the topics you are interested in. Check the box to have a cleanwater1 expert contact you within one business day.

Additional Resources

Learn At Your Pace

By subscribing to our learning track, you will receive emails featuring videos, webinar invites, informative articles and more.

View Our Online Library

Featuring brochures, case studies, data sheets and more. Filter by product category, brand, location, use case or document type.

Connect With Us

Contact a member of our team using our online form, by email or give us a call. We look forward to speaking with you.