Varea-Meter® and Arma-View®II

Variable Area Flow Meters

A Long History of Reliability and Control

For over 60 years, our broad line of rotameter-type flow meters have provided reliable readout, transmission, and control of liquids or gases for most industrial process and water treatment applications. We offer a variety of flow meters to choose from:

- For low-capacity, low-pressure applications, we offer glass tube purge meters with stainless steel frames.

- For low-flow, higher pressure applications, armored purge meters are our recommendation.

- For high volume flows, glass-tube and metal tube meters are available in a variety of sizes and configurations for accurate metering of both air and liquids.

- Purge meters are designed for purging instruments, cases, and control lines and are readily adapted to liquid-level indication, sampling, liquid-specific gravity determination, and similar applications.

Armored Purge Meters are ideal for low-flow, higher pressure applications.

Flow meters are an important tool for ensuring that water treatment facilities operate efficiently and effectively, producing high-quality water that is safe for consumption.

Flow Meters Ensure Water Treatment Facilities Operate Efficiently and Effectively

Flow meters are used in water treatment facilities to measure the flow rate of water as it moves through various stages of the treatment process. They are an essential tool for ensuring that the treatment process is functioning as intended, and that the water being treated is of sufficient quality.

Some specific applications of flow meters in water treatment include:

- Monitoring influent and effluent flow rates. Flow meters can be used to measure the amount of water entering and leaving a treatment facility, helping to ensure that the treatment process is effectively removing contaminants.

- Controlling chemical dosing. Some types of flow meters can be used to control the rate at which chemicals are added to the water, such as coagulants or disinfectants. This ensures that the correct amount of chemicals are added, improving the efficacy of the treatment process.

- Monitoring flow rates through treatment stages. Flow meters can be installed at various points in the treatment process to monitor the flow rate of water through each stage. This allows operators to identify any blockages or issues that may be affecting treatment efficiency.

- Billing and regulatory compliance. Flow meters can be used to accurately measure the amount of water being processed by a treatment facility, which is important for billing customers or complying with regulatory requirements.

Our Assortment of Meters Have the Highest Accuracy Rates in the Industry

Glass Tube Purge Meter

Glass tube purge meters have a rugged stainless steel frame, are available in 1½- inch and 3-inch scale lengths and use a high-stability float for accurate, repeatable performance. Meters can be supplied with flow controllers and plastic bezels for flush mounting (not available with 1½-inch scale purge meter).

Standard meters calibrations are in CCM, GPH, SCCM, SCFH and PERCENT.

All meters feature an optional built-in flow-control valve, horizontal inlet and outlet connections and an external threaded tube locking plug for easy tube removal. An optional purge type flow controller is available for inlet or outlet mounting.

Features

- Unique one piece frame design for strength and rigidity.

- Easy-to-remove metering tube.

- Choice of percent or engineering units.

- Positive tube locking mechanism.

- Maximum capacities from .32 CCM to 40 GPH Water, 30 SCCM to 110 SCFH air at STP.

Benefits

- Rugged for extreme conditions

- Accurate, repeatable performance

- Multiple configurations available

- Easy tube removal

- Optional flow controllers available for inlet or outlet mounting.

Arma-View®II Purge Meter

The Arma-View® II Low Flow Armored Purge Meter is designed for the measurement of low volume flows of aggressive chemicals. The 316 stainless steel meter construction provides reliable metering of gases and liquids at high pressure and temperature ratings.

Low-flow, high-temperature and pressure applications are available with optional 4-20mA transmitter and flow controller. An optional FM-approved hazardous location 4-20mA transmitter provides remote indication of flow rate. An optional purge-type flow controller keeps flow constant regardless of pressure variations. It is offered for inlet and outlet configurations, and can be assembled to the meter or as a stand- alone in the process line.

Features

- Easy readability

- True magnetic coupling

- Versatility and convenience

- Rugged construction

Benefits

- Reliable, low metering of gases or liquids

- Remote indication of flow rate via an electronic transmitter

- FM approved configuration for hazardous areas

- Optional flow controller to maintain constant flow

Armored Purge Meters - Metal Frame

The Armored Purge Meter operates over a 10:1 range. Scales are 1¼ inches long. The ½-inch meter has a GPH or SCFH scale; the ¾-inch meter, a GPM or SCFM scale. Each also has a percent scale.

The snubber on the magnetic float causes readings to steady out quickly. This gives true readings down to atmospheric pressures. The O-ring at the top of the float seals against the seat to prevent back flow through the meter. A port in the bottom of the meter body makes it easy to clean.

The stainless steel and welds in our Armored Purge Meters resists sulfides by conforming to NACE Standard MR-01-75 covering hydrogen sulfide-resistant surfaces. The 316 stainless steel body with Buna N or TFE O-rings gives corrosion resistance and reliable operation to 1500 psi (10 bar) and 800°F (427°C) (600°F (316°C) with flow switch).

At no time is the glass scale tube exposed to the process fluid. A stainless steel sheath encloses the O-ring sealed glass tube. General purpose or hazardous area flow switches are available.

Features

- Rugged construction

- Resists attack by sulfides

- Accurate gas metering

- Built-in backcheck

- Easy to clean

Benefits

- Reduced maintenance cost without removing meter from service

- Stands up to extreme conditions with rugged construction

- Reliable long term performance in gas or liquid service

- Highly accurate and stable readings for precise measurement and control

- Easily adaptable to fit your exact needs with standard options

Armored Flow Meters - Series 55-200

The Series 55-200 Armored Flow Meter is an inexpensive, 5% accuracy flowmeter. This 316 stainless steel meter gives reliable flow indication of aggressive fluids making it ideal for high-pressure and high-temperature flow applications. Its plug and orifice design, overall simplicity, and minimal parts add up to an economical meter.

Size for size, our Armored Flow Meters provide high capacities, reliable indication and transmission of flow, and dependable service.

Features

- Available options include a 4-20mA output flow signal and high/low alarm switch.

- Meter sizes (pipe connections) are ½-, 1-, 1½-, and 2- inches FNPT with capacities up to 130 GPM (492 LPM) water and 150 SCFM (4200 LPM) air at STP.

- Operating range is 10:1.

- Mounting is vertical in line with NPT female connections.

- All wetted parts are stainless steel (except polypropylene and TFE floats); Buna-N, Viton® or EPR O-rings.

- The float has an encapsulated alnico magnet.

Benefits

- Economic metering and service

- Higher capacities then other designs

- Stable readings

- Reliable flow indication

- Field convertible electronic transmitter

Glass Tube Varea-Meter® Flow Meter

Varea-Meters units are designed for precise measurement of liquid and gas flow rates. Metering accuracy is 2% of full scale over a 10:1 range. The advanced design of the float and the tapered tube extends the meter capacity to match that of comparable meters costing much more.

Varea-Meter® flow meters are available in a wide variety of tube sizes and configurations. The glass tube version includes a one piece stainless steel frame and beaded guide tube with a detached scale for calibration in most engineering units.

Tube sizes are available from 3/8" to 1 1/2". Frame sizes can be 5" or 10". The end fitting material is available in 316 stainless steel or PVC. Standard float construction is 316 stainless steel (Hastelloy "C" is optional).

Beaded guide tubes are available with 5- or 10-inch scales. End fittings for vertical and horizontal connections come in NPT sizes. Choice of wetted parts materials such as 316 stainless, Kynar®, Buna-N, and Viton® give a good balance between cost and maximum corrosion resistance.

Features

- Rugged one piece enclosure makes for easy installation

- Positive tube seating and easy tube removal

- Variety of connection sizes

- Convenient capacity changes

- Accuracy 2% full scale standard

- Capacity .24 GPM to 59.9 GPM water or 1.0 to 281 SCFM air

Benefits

- Protects your investment with a longer lifespan than other meters

- Easily installed in any piping system

- Reliable long term performance in gas or liquid service

- Highly accurate and stable readings for precise measurement and control

- Reduced maintenance costs compared to other meters

Metal Tube Varea-Meter® Flow Meters

Metal Tube Varea-Meter® Variable Flow Meters are designed for the measurement of high-volume flows of aggressive liquids and gases. The advanced design of the float and the tapered tube extends the meter capacity to match that of comparable meters costing much more. The 316 stainless steel construction makes these meters suitable for a broad spectrum of applications.

Metal Tube Varea-Meter® Variable Flow Meters are easy to install, calibrate and configure. They provide reliable long term performance in gas or liquid service. Available in a variety of tube sizes (½-, ¾-, 1-, and 1½ inches) and flange facings and ratings, these flow meters measure over a 10:1 range for aggressive fluids at high temperatures and pressures. Metering accuracy is 2% of full scale.

Anti-Magnetic Particle Float has a reduced flux density and is located above the metering disk. This discourages accumulation of magnetic particles, especially on the disk edge where they can cause errors in indication. Meter design directs the flow into a pattern, which scrubs the float and guides clean. The Metal Tube Varea-Meter® unit is ideal for suspensions and slurries.

When the float is at rest, nothing projects beyond the flanges. Spool pieces are not required for installation and a frequent cause of damage when removing meters from a line is gone. In and out piping is vertical.

For reliable indication, a powerful magnetic linkage exists between the float magnet and the indicator magnets. Transmission and indication are reliable even under sudden flow surges.

The indicator unit, with optional 4-20mA transmitter or flow switch, are independent. A mounting clamp attaches each to the meter tube. The same clamp attaches the transmitter or flow switch 180 degrees from the indicator unit. Clearance between any of these units and the tube leaves room for steam or electric tracing.

Features

- Anti-Magnetic-Particle float

- No float extensions

- Reliable magnetic coupling

- Easy conversion from flow indication only to flow transmission

- Standard tube-and-float material is 316 stainless steel; a Hastelloy® C float is also available.

- Options include a 4-20 mA FM approved hazardous locations transmitter for remote indication of flow rate.

- External alarm switches are available for high/low flow alarm.

Benefits

- Simple to install, calibrate and configure

- Reliable long term performance in gas or liquid service

- Highly accurate and stable readings for precise measurement and control

- Stands up to extreme conditions with rugged construction

- Easily adaptable to fit your exact needs with standard options

- Ideal for suspensions and slurries

- Transmission and indication are reliable even under sudden flow surges

Product Details

Accessories

Flow Controllers

The flow measurement product line offers three types of flow controllers:

- Series 5700 General Purpose Flow Controller

- Series 5750 High Pressure Flow Controller

- Series 5800 Purge Type Flow Controller.

Each is designed to maintain a constant set flow rate regardless of variations in the line pressure. All of these basic arrangements are suitable for gas and liquid service.

The Series 5700 General Purpose type has a broad range of applications. It can be used with almost any equipment or within any flow system in which the process fluid is compatible with 316 stainless steel construction.

It is ideally suited for the Armored Purge Meters, Armored Flow Meters, Glass-tube Varea-Meter® units, or as a stand-alone controller with other meter types.

The Series 5800 and 5750 purge type flow controllers are engineered specifically for use with the Glass-tube Purge Meters, Low-flow Meters, and Arma-View®II Armored Purge Meters. The Series 5800 purge-type flow controller is engineered specifically for use with glass-tube purge meters. The Series 5750 high pressure flow controller is designed for use with purge meters in high pressure and temperature applications (1000 PSI and 400 degF MAX). Both the 5800 and 5750 series controllers are offered in an inlet or outlet flow configuration for added versatility.

Features

- Simple, Direct Design. The clean, straight-through design makes it simple to integrate these controllers within a system. Installation piping is direct and uncomplicated.

- Reliable and Accurate Operation. These controllers maintain a constant set flow rate by sustaining a constant pressure drop across their orifices. The size of the orifice is varied while the pressure drop is held constant. This balance provides a set flow despite changes in the supply pressures.

-

Sturdy Construction. The housing and valve stem for all controllers is constructed of 316 SS, while the diaphragm is made from highly chemical resistant Teflon material.

Key Benefits

- Choice of integral and stand alone design allows for flexible installation options

- Easily adapt to existing meters

- Reliable and accurate operation despite changes in the supply pressures

- Chemically resistant to many process conditions

- Wide spectrum of flow rates and pressures allowable

- Easy to integrate controllers within the system with direct and uncomplicated

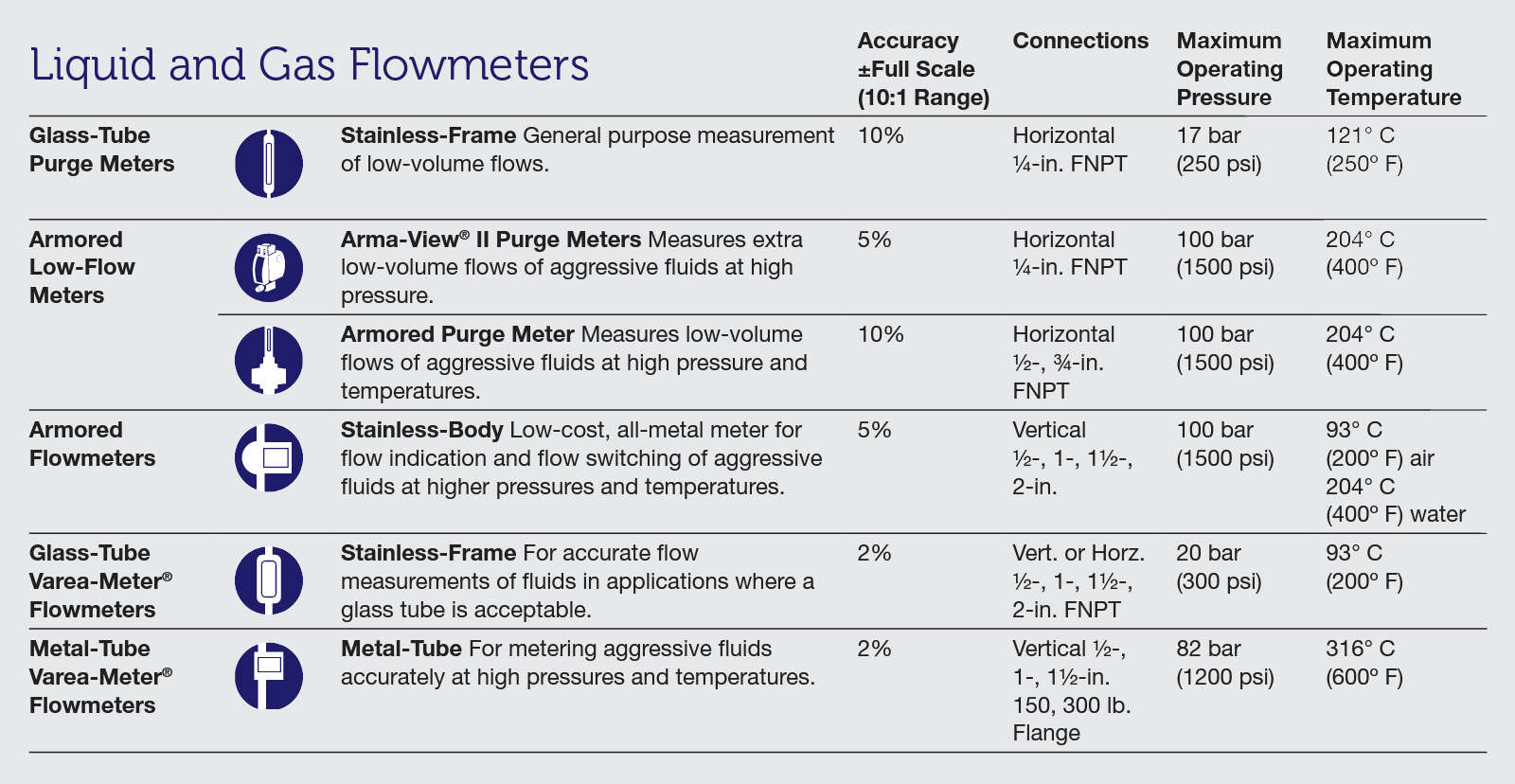

Liquid and Gas Flow Meters

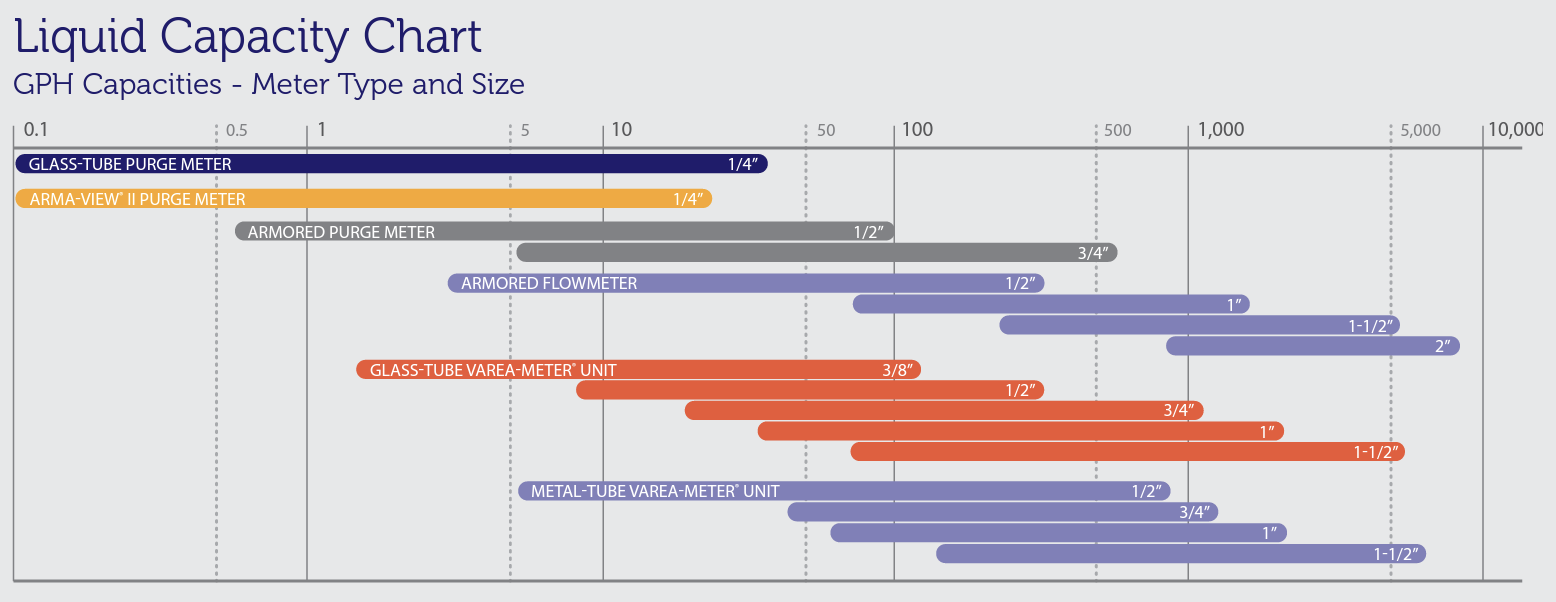

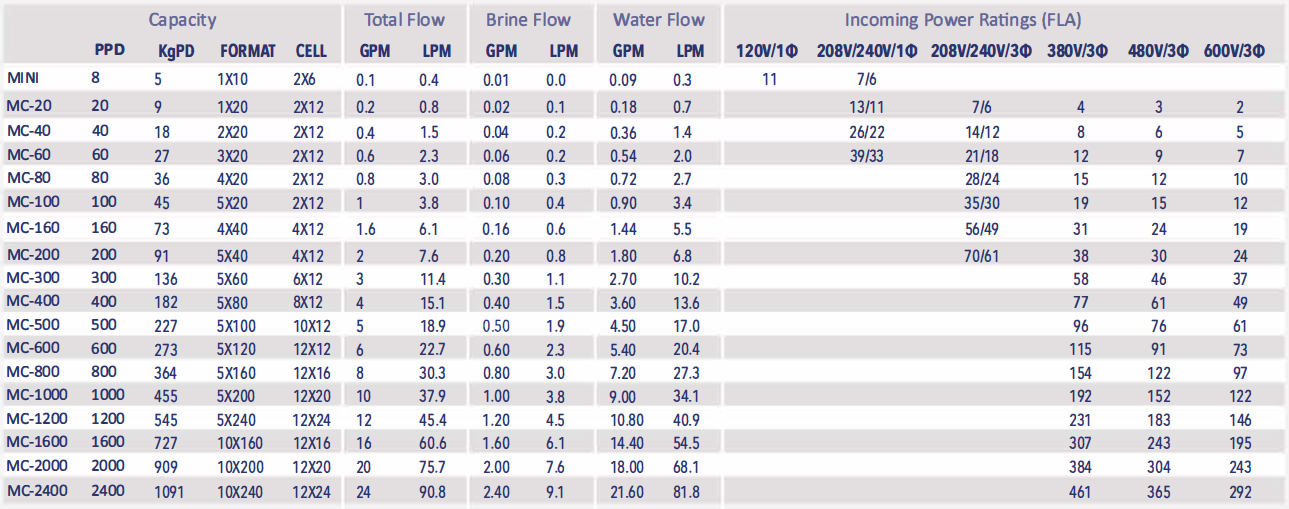

Liquid Capacity Chart

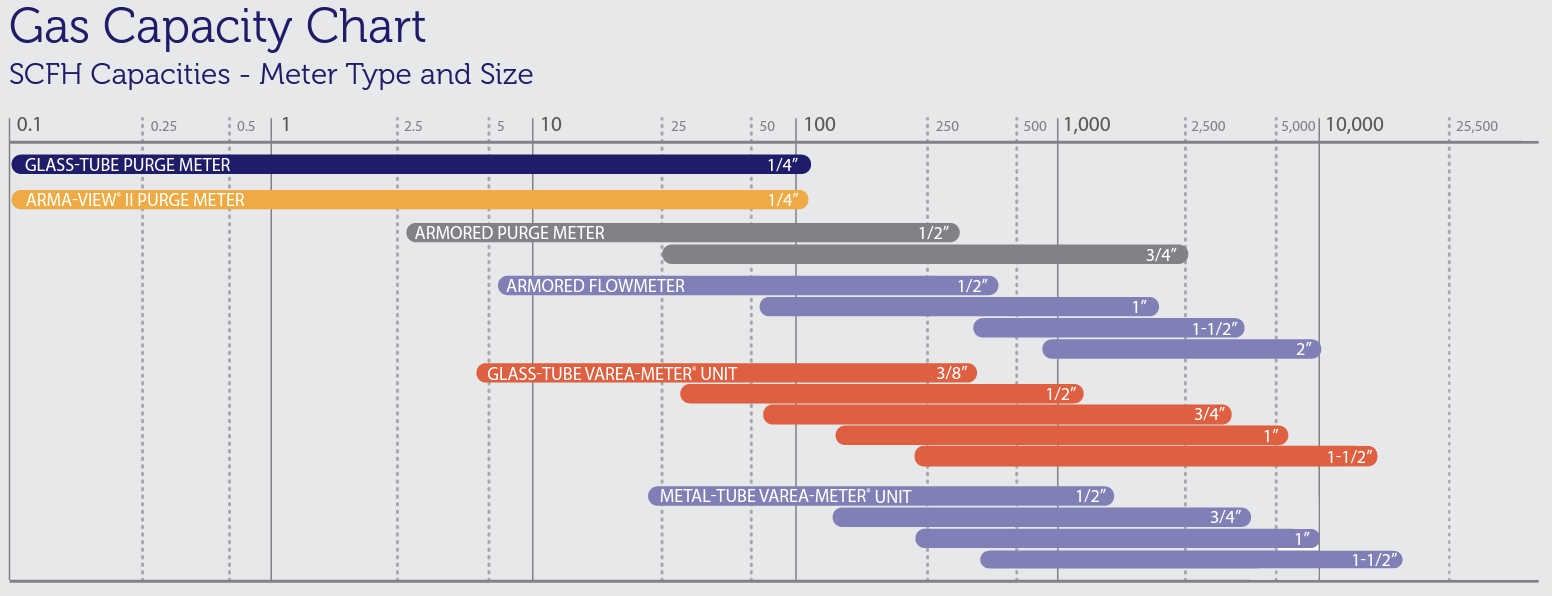

Gas Capacity Chart

Trademark Disclaimer

Benefits of Varea-Meter® Flow Meters

Easy to Install, Calibrate and Configure

Highly accurate and stable readings for precise measurement and control

Rugged Construction for Extreme Conditions

Let's get the conversation started

Tell us a little bit about you and the information you’re looking for and we'll send you information by email about the topics you are interested in. Check the box to have a cleanwater1 expert contact you within one business day.

Additional Resources

Learn At Your Pace

By subscribing to our learning track, you will receive emails featuring videos, webinar invites, informative articles and more.

View Our Online Library

Featuring brochures, case studies, data sheets and more. Filter by product category, brand, location, use case or document type.

Connect With Us

Contact a member of our team using our online form, by email or give us a call. We look forward to speaking with you.