Dry Chemical Processing

Small Bag Systems

VeloDyne's small bag systems are designed for safely unloading small bags of chemical into a hopper and precisely metering the chemical with the Barracuda volumetric or loss-in-weight feeder to into a wetting bowl or mix tank system.

Features

- Barracuda volumetric feeder with overwind & hopper vibrator material conditioning (see Barracuda brochure for feed rate options)

- Mix tank or wetting cone with dilution water control system

- Batch level control, direct feed flow-through over-flow or metered control options

Bulk Bag Systems

The VeloDyne Bulk Bag System is a product designed for medium feed rate applications. The Bulk Bag System is typically delivered in two pieces for a simple installation. Pumps can be integrated to the Bulk Bag System for applications that require pumping to the next process point.

Features

- 100-4000 Pound Bulk Handling Capacity

- Heavy Duty Welded Tubular Frame Construction

- Easily Configure Options for Custom Applications

Volumetric Feeders

The feeder is the heart of our systems. As a stand-alone component, a properly sized feeder can meter a specified amount of product into a finished package. As an integral part of a system, the same properly sized feeder can meter minor ingredients to a food batching system, lime or polymer into an environmental water system or chemicals into a fertilizer blend.

Features

- Barracuda volumetric feeder with overwind & hopper vibrator material conditioning (see Barracuda brochure for feed rate options)

- Mix tank or wetting cone with dilution water control system

- Batch level control, direct feed flow-through over-flow or metered control options

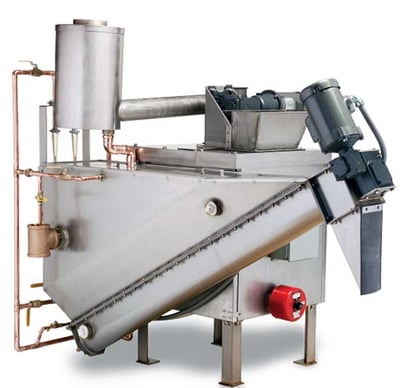

Lime Slakers

VeloDyne's MAKO High Density Lime (HDL) systems are used in a variety of municipal and industrial water and wastewater treatment processes. Our technology reduces scaling in pipes and maintenance of equipment common with standard lime slurry systems.

Features

- MAKOTM HDL slurry make-down system is a proven design using state-of-the-art Computational Fluid Dynamics (CFD) to optimize slurry mixing

- Local control system with programmable logic controller (PLC) and color touch screen

- Weight and density monitoring and control

Silo Systems

VeloDyne Silo Systems are used in municipal and industrial water and wastewater treatment. The systems store, feed, dissolve, and deliver chemical to the desired process point.

Features

- Traditional Two Piece Welded Silo System Design (optional bolted design)

- Conduit, Wire, and Plumbing Installed Under Floor, Against Wall or Overhead

- Silo Components Completely Hydrostatically and Electrically Tested